In virtually every instance, significant performance reserves that are not revealed simply by studying the technical data in the catalogue can be leveraged as a consequence of direct contact with customers and their applications.

Delta robots tend to be unique - with big implications for the drives WITTENSTEIN has been designing transmission and actuator solutions for delta robots for almost a decade. Their diversity is enormous - hardly any two robots are alike. The handling tasks presented for evaluation call for robots with two, three or sometimes four axes, the products and product weights vary, the pick & place distances differ from one facility to the next and so on. The challenges almost invariably involve very high cycle numbers and short, highly dynamic motions in a high duty cycle. Account must also be taken of the place of installation and the mounting position of the gearheads and actuators, especially in food processing applications. The individual axis drives are subjected to manifold operating loads, and superimposed tilting moments and torques often act on the output. At the same time, absolute reliability is essential because the majority of delta robots are located at the end of a product's value chain, for example on a confectionery packaging line. WITTENSTEIN's engineering experience offers ample confirmation that the transmission and actuator solutions are as individual as the delta robots themselves.

WITTENSTEIN experts share know-how that can't be found in the catalogue

From the point of view of the drive technology, in other words, there is no such thing as a standard application for delta robots. As a result, choosing a transmission or actuator solution "off the peg" is bound to be suboptimal in terms of the delta robot's performance, flexibility, stability and availability. On the other hand, by resorting to WITTENSTEIN's vast expertise and taking advantage of its know-how, customers acquire an effective guarantee that each delta robot will be pushed to its performance limits - a precondition of maximum efficiency in the end user's production environment.

The first step in designing a drive solution for delta robots is to analyze the task at hand in the context of any general conditions and constraints. Initial, theoretical calculations are performed on this basis in order to map the multidimensional motions in space and determine interactions with other moving components of the robot. Real torques, load data and potential dynamic effects, for instance if the drive system begins to vibrate, are then calculated in detail and optimized with the help of a so-called multibody simulation. It is also important at this stage to identify what are referred to as overload factors and exploit them to achieve extended design and application areas or greater energy efficiency as well as to downsize the delta robot's entire drive train. The technically controllable power reserves that are tapped in this way frequently go far beyond the product-specific data contained in the catalogue.

Software, sensors and system tests add up to the optimal gearhead

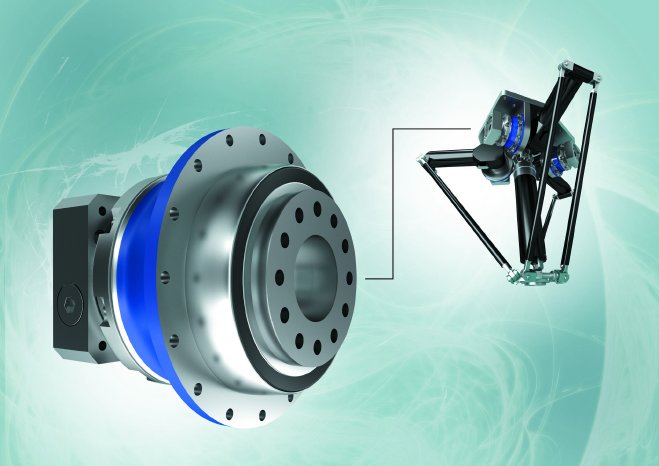

The cymex® 3 software package developed by WITTENSTEIN makes a valuable contribution as the drive planning process for a delta robot progresses. It sizes the application, motor and gearhead - that is to say, the complete mechatronic drive solution - according to the information generated by the multibody simulation, then simulates and evaluates the efficiency of their interaction. The result is an optimal recommendation inspired by the WITTENSTEIN portfolio - either a straightforward transmission solution belonging to the TP+ series or a motor-gearhead system in the TPM+ range. Standard and high-torque versions are available in both cases. Another very useful development tool on the way to the perfect drive solution is WITTENSTEIN's modular torqXis sensor system. Amongst other things, it allows the drives to be monitored when the delta robots are tested in a real environment at the engineering manufacturer's facility, for example to measure torques, lateral forces and temperature directly in the drive train. The actual data obtained in this way is founded on practical operation and can often be utilized to further optimize the gearhead and actuator design. Owing to the preliminary work and engineering know-how contributed by WITTENSTEIN during the planning phase, the number and scope of these iteration steps are minimized, leading to a massive reduction in the time to market for the delta robot.

At a glance:

Three outstanding advantages of WITTENSTEIN:

Engineering know-how, methodological and software expertise and a portfolio of high-performance products from a single supplier

With its combination of longstanding engineering experience, acknowledged methodological and software expertise and a product portfolio comprised of powerful drive solutions that also supports modular robot concepts, WITTENSTEIN offers delta robot manufacturers the security of a technically and commercially optimized drive design for highly dynamic and multidimensional motion profiles. WITTENSTEIN gearheads are installed in delta robots from a variety of manufacturers. And this great success story is still continuing, as demonstrated by the new, easy-to-clean, hygienic TP+ washdown gearhead specially developed by WITTENSTEIN for delta robots in the food processing industry.