In this version there are two different clamping possibilities on the top and bottom. One side is designed for fixing to a base and the opposite side is configured to clamp the actual workpiece.

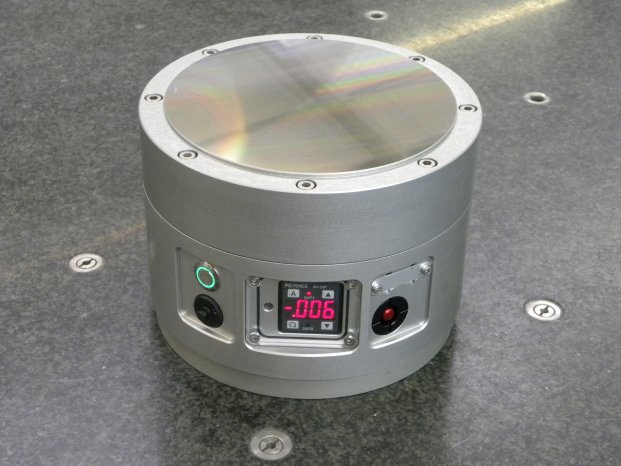

The basic unit is fully automatic and has an integrated, self-monitoring module for generating vacuum. Once clamping procedure has been triggered manually by pressing a button, the workpiece is immediately clamped and operating vacuum is permanently maintained until machining is complete. This is possible due to a pump and controls built in to the vacuum chuck.

Manufacturing in milling or grinding machines or other processes is possible completely detached from all power supply for clamping parts. Likewise, the chucks can be used with pallet changing operations, where the pre-loaded parts are retrieved from a pallet station.