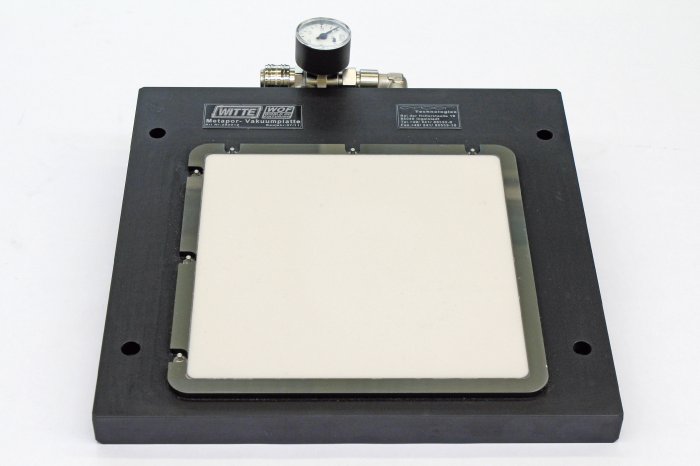

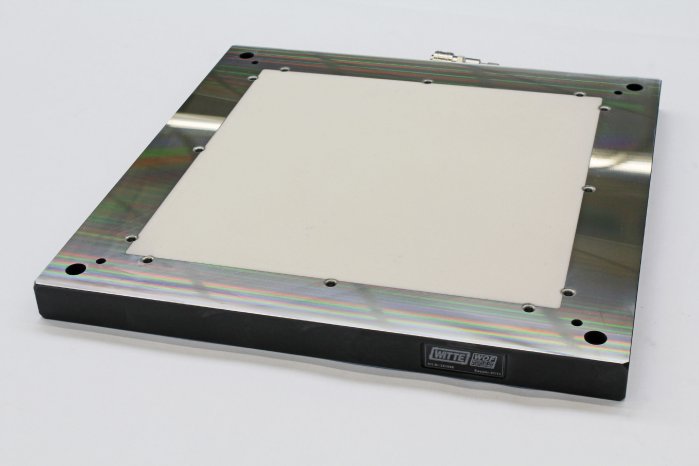

These light but nevertheless accurate vacuum chucks made of aluminium alloys are especially suitable for workpiece handling on machining centers, whereas the stainless steel versions are designed for the actual machining job. Extremely thin workpieces or foils i.e. 0,01 mm thickness can be clamped evenly and securely on areas made of microporous Metapor(TM) .

Flexible:

Apart from the standard circular or square versions upto several square meters, Witte Vacuum Chucks can be supplied according to customers request and the specific contours and geometry of the workpiece involved. They are therefore suitable for both one-offs and series production- Individual design - according to your requirements.

Accurate:

The high quality measuring machines and fixtures in our climate controlled measuring department guarantee high accuracy, even for large batch sizes. Witte vacuum chucks can be supplied with a eveness and and parallelism of approx. 3-5μm.

Reliable:

The vacuum clamping area is made of a microporous material which ensures a flat clamping without deformations thru vacuum holes or other vacuum supplies. Its high porosity of approx 45% together with a medium grain size of approx. 30 μm allow gentle fixation of workpieces with a strong holding force. The light weight combined with the the accuracy of Witte Vacuum Chucks ensure trouble-free machining in automated systems.

Universal:

Witte Vacuum Chucks are especially suitable for fast and secure clamping of wafer plates made of silicium or polyamide in the semi-conductor industry Because of their own special properties they can also be used in:

- Optical industry

- Research and development

- Foil measuring

- Measuring technology

Complete systems:

Witte-Gerätebau will supply you with equipment custom built for your application or with modular standard components. All required accessories from a simple pump to powerful vacuum units, rotating joints, hoses, additional vacuum tanks, magnetic valves right up to automatic liquid separators are available short-term.