At Klostermann the variety of parts to check is very comprehensive and range from small plastic parts to heavy, large volume cast parts. As the company based in Remscheid, Germany, monitors product development, frequently from prototype production up to process-controlled series-production, repeatability of the fixtures also plays an important role. To minimize preparation times, while being able to remount a part in exactly the same position on the measuring machine, fixtures are documented with one or two digital photos. That enables a complete rebuild of an identical, accurate fixture in the shortest possible time.

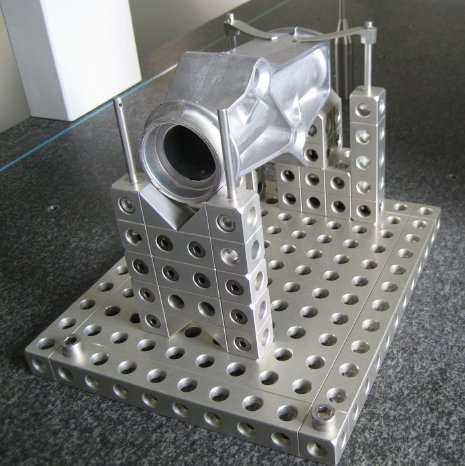

"Flexible fixturing is extremely important especially for a measuring service provider. In the morning we might be measuring a 350 kg heavy gearbox housing mounted on Alufix 25 and in the afternoon components of the same fixture would be used for medical technology parts weighing only a few grammes. And all with the same, consistent precision ", explained Christian Klostermann, procurist in the Klostermann company.

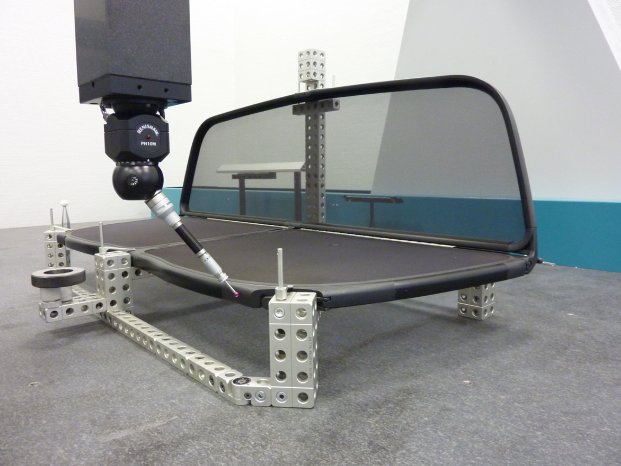

Apart from flexibility, the speed of assembly is also important. At Klostermann measuring fixtures for large automotive plastic parts are ready within 15 minutes. Christian Klostermann acknowledges "We really enjoy building fixtures too because the precision of the aluminum components fascinates us again and again".

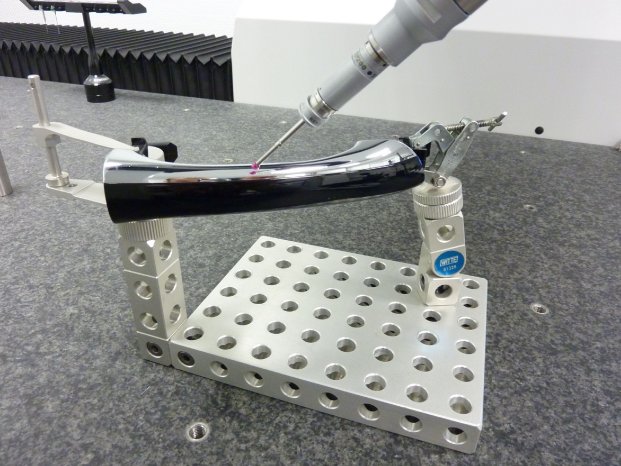

Even complex shaped parts, like the door handle of a luxury coupé, can be prepared quickly on Alufix for initial sample testing. It is important to cover the least possible surface with the elements but at the same time to position the part securely and repeatably. (Fig. 002)

As Klostermann GmbH also markets measuring machines, high-quality equipment must be used for customer demos. " Customers often bring along their own workpieces, which we have never seen before, to our demonstrations," explains Sebastian Teichmann from the Customer Care department. "Naturally it creates a professional impression, when the parts brought in are mounted on a custom-built, dedicated fixture in no time at all so to speak." Often an individual Alufix kit is assembled together directly with the customer.

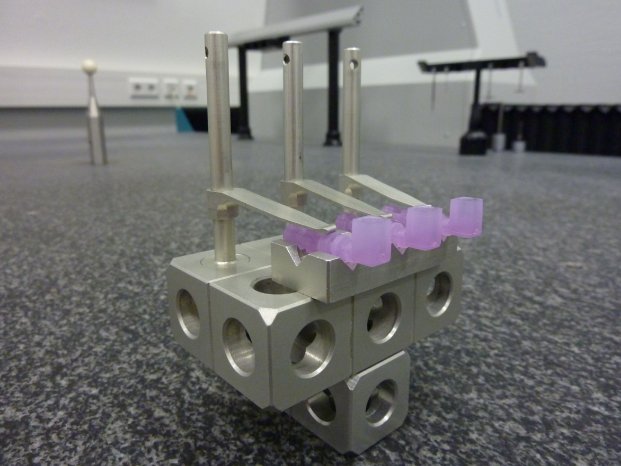

Even people, who have never been involved with the topic 'fixture building' get along fine with the simple principle of Alufix very quickly. The system is available in system 16, 25, 40 and 50, which are combined using connection elements. The numbers describe in each case the distance between centre hole and centre hole. Alufix comprises of highly accurately machined high-tensile aluminum components which are configured into custom built measuring fixtures and joined using connection elements. Apart from high precision particularly the multiple application possibilities for users are interesting.

Klostermann's experience shows that for customers, who ordered an Alufix set with their new measuring machine, the subject of fixture building sells itself. "The goal of not only positioning parts accurately and securely but also fast and repeatably on a measuring machine is quickly achieved with Alufix modular fixturing system" emphasizes Sebastian Teichmann. In addition, the life span of a fixturing system is also a strong argument for users. Christian Klostermann is particularly fascinated by the combination options of "old "components with the current parts from Witte's Alufix 25 System. The individual parts always fit, whether they were purchased in the 1990 or 2010. "Alufix is a worthwhile investment, because the components last a lifetime and show hardly any wear", insists Christian Klostermann.

Klostermann GmbH - 3D Measuring Technology from Remscheid

As a dealer for leading manufacturers Klostermann sells - exclusively in North-Rhine-Westphalia - 3D measuring machines. Their range covers tactile and optical measuring machines, high-speed digitizing systems as well as X-Ray and CT-equipment, and is complemented with services such as commissioning of equipment, calibration and subcontracting measuring, currently with 14 different measuring possibilities.

Founded in 1979 in Wuppertal as a distributing company for machine tools in recent years Klostermann GmbH sold more than 550 new measuring machines. 19 staff are involved with 3D-measuring technology with a lot of commitment and performance on a daily basis.

www.Lohnmesstechnik.de

Klostermann Ingenieurbüro und Vertriebsgesellschaft mbH

At the Hasenjagd 5,

42897 Remscheid

Telephone 0 21 91/60 90 4-0,

Telefax 0 21 91/60 90 411,

www.klostermann.com,

mail@klostermann.com