The new WISKA HatGLAND cable gland is resistant against contamination, robust and very tight against chemical and high-pressure cleaning - all of which are particularly important for sensitive industries such as food production, where machines and plants need to be designed according to high hygiene requirements. This applies to housings and cable glands just as well. The components are subject to extreme cleaning processes that they need to resist in any case.

Give Contamination No Chance Grooves, pockets, recesses or protrusions where dirt particles can collect were consistently avoided when HatGLAND was developed. The new cable gland also has an over-proportionally slanted build with an inclination of 25 percent, ensuring quick runoff of liquids. The gap-free sealing concept of hygiene- compliant material and a seal equipped either with EPDM, silicon or FDA-approved elastomers give foreign materials no chance of entering the housing and impairing operation. Another effect is a reduction of the cleaning and maintenance effort.

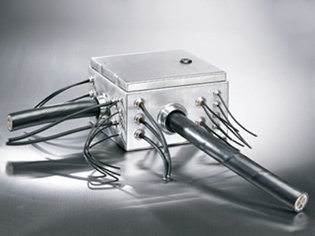

Great Interest from Hygiene-Sensitive Industries The high requirements to cleanliness and cleaning make the dirt-repellent, tight design of the Hat- GLAND ideal for use in the food industry, medical and clean-room technology, biotechnology and chemical industry. "We first presented the HatGLAND cable gland to a specialist audience on this year's architecture and technology exhibition Light+Building in Frankfurt am Main and on the world's largest industry trade fair in Hanover," says Ronald Hoppmann, General Manager of WISKA. "In particular the food and chemical industries showed an extraordinary interest." The stainless steel gland is installed easily from the inside with a locknut through oblong holes at nominal sizes of 12 to 63 mm.

Housing wall thicknesses of up to 10 mm are possible. HatGLAND is also available as an EMC version.