- OMNIMATE® Power male headers with THR solder connection allow for complete SMT production.

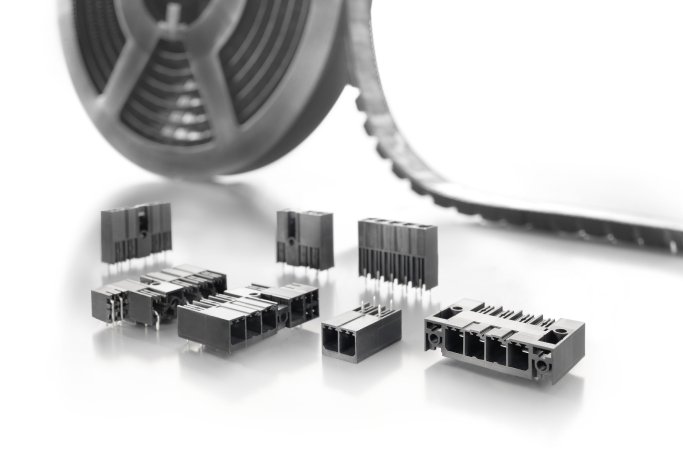

The OMNIMATE® Power SV-SMT male headers meet the requirements for fully automatic PCB assembly using an SMT soldering process (reflow process). Thanks to the tape-on-reel packaging in standard tape widths from 24 mm, the male headers can be efficiently processed together with the component assembly in a single production process. Large suction areas allow for the secure suctioning and precise positioning and setting down of the male headers. The headers are precisely manufactured, i.e. the position tolerance of the solder pins meets the specifications of standard IEC 61760-3. Weidmüller uses an insulating material with a high temperature resistance and a high tracking resistance (CTI value - Comparative Tracking Index) for its OMNIMATE® Power SV-SMT male headers, meaning that they do not have any voltage range restrictions compared to conventional THT products. The pin length is process-optimised for the THR soldering process (through-hole reflow). The entire range of products in the OMNIMATE® Power SV 7.62 male header family are all available as THR versions. Existing THT designs can be easily converted to SMT production with its high level of automation. OMNIMATE® Power SV-SMT male headers are part of the most comprehensive product range that Weidmüller currently offers for the SMT process.

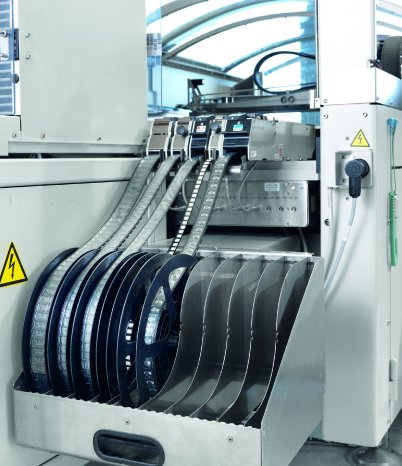

Increasing requirements such as the demand for miniaturisation, greater functionality within modules and cost-effective manufacturing processes have led to changes to PCB assembly processes – and this applies in particular in the area of power electronics. Surface-mount technology (SMT) is increasingly being used in practical applications instead of conventional through-hole technology (THT). The SMT process has now established itself as the standard in the processing of electronic components, and is now also used in the production of power electronics. Weidmüller has addressed this trend with the OMNIMATE® Power SV-SMT male headers. In order to ensure efficient assembly, the male headers are supplied in tape-on-reel pacakging for standard tape widths. The components are removed from the component feeder using a vacuum pipette in the pick-and-place station. The Weidmüller SMT products have a large suction surface in order to ensure secure and precise positioning.

The OMNIMATE® Power SV-SMT male headers are made from a high-temperature-resistant insulating material, meaning that they can withstand the high processing temperatures generated during the reflow soldering process. Dimensional stability and pitch accuracy are also guaranteed. The insulating material also has a high tracking resistance (CTI value), so the male headers do not have any voltage range restrictions compared to conventional THT products. The CTI value indicates the maximum voltage at which the base material does not have any conductivity.

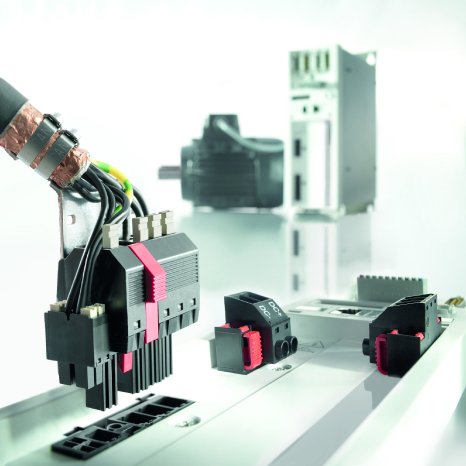

The OMNIMATE® Power SV-SMT male headers give device developers a high level of design freedom in the field of power electronics, as well as opening up potential savings in the case of existing device or PCB designs. Existing THT designs can be easily converted to SMT production with its high level of automation. The male headers can be produced together with the component assembly in a single process, which ensures efficient PCB production within power electronics. An uninterrupted production process from automatic machine assembly to soldering is guaranteed, thus saving time and money.

As one of the leading suppliers and pioneers of device connectivity, Weidmüller offers the widest existing range of products for the SMT process currently on the market. Connection components in THR and SMD versions support high efficiency in device manufacturing throughout the entire electronics sector.

OMNIMATE® - service

With four service packages, the OMNIMATE® Device Technology division supports its customers in the development of innovative devices. The service packages include a comprehensive component library for PCB design software, the "application-oriented product recommendation" Internet-based selection aid AppGuide, and the well-established 72-hour sample service. With this sample service, device designers won't lose any time; Weidmüller will deliver samples of its device connection components and electronic housings to you within 72 hours, whatever your location – including the OMNIMATE® Power SV-SMT male headers. Handling videos of the OMNIMATE® products can be found on the Weidmüller YouTube channel.

Weidmüller – electrical connection, transmission and conversion of power, signals and data in the industrial environment. – Let’s connect.

Additional information: www.weidmueller.com; www.weidmueller.de/AppGuide

www.weidmueller.de/omnimate; www.weidmueller.com/omnimate