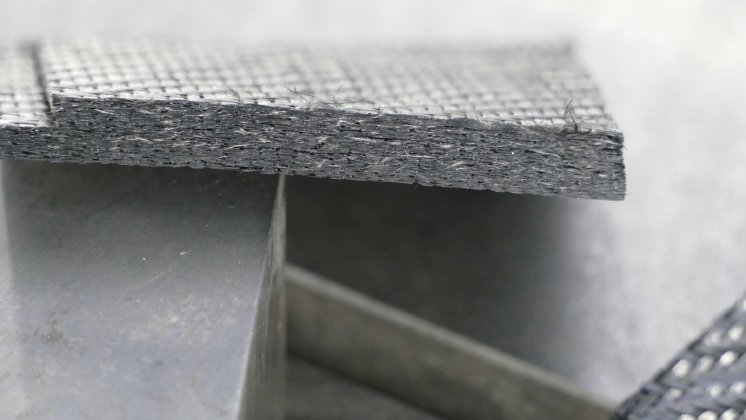

The use of lightweight materials such as fiber-reinforced plastics, composites and stacks with cores of foam or honeycomb structures demands frequently modified processing solutions. Ultrasonic systems for milling, cutting and sawing provide adaptable and efficient processes.

Non-resonant systems generally used today convert only about five percent of input energy into vibrations. In contrast, the resonant ultrasonic systems jointly developed by Hufschmied Zerspanungssysteme GmbH and Weber Ultrasonics AG achieve an efficiency rate of 90 to 95 percent. Among other things, the systems use significantly reduced process forces. In the processing of glass fiber and carbon, for example, the material removal rate is higher, resulting in higher material throughput and reduced machine working time. In addition, the tool life is increased through decreased strain or deformity of the tools. Processes are thus made more efficient.

Greater processing accuracy also can be achieved in ultrasonic milling with the new resonant systems. Delicate workpieces, for instance, can be manufactured with gantry systems. Furthermore, it is possible to use industrial robots as economical and flexible alternatives for the implementation of an automated production process. The feasible production tolerances lie within the relative accuracy range of classic machine tools.

Fakuma: Hall 4, Stand A4-4200