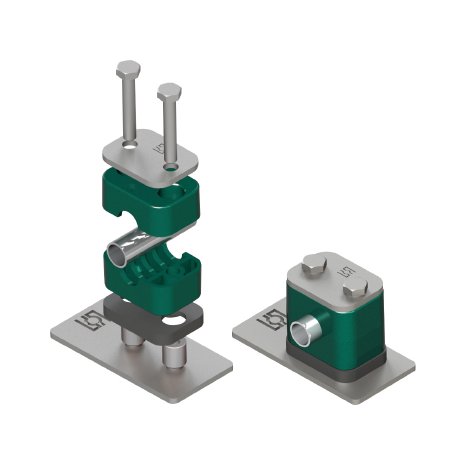

The weld studs – which to date have only been available in copper-coated steel – feature an M6 female thread and replace the weld plates usually used to fix standard tube, hose and cable clamps in line with DIN 3015 (Part 1). This functional principle can also be transferred to other popular fixing elements, if required, such as for clamping belts, cable ties or corrugated cable protection hoses. The joint produced stands out on account of its excellent stability and the fast and hence cost-effective installation of the clamps. In many applications, including industrial lightweight construction, stud welding is also the only technically feasible solution for fixing clamps onto the substructure.

This addition of stainless steel weld studs to the range enables the benefits of this joining technique to be used where stainless steel is predominantly used as a material as well. This applies, among others, to the marine and offshore sector, for assembly, tank and container construction, and to the process chemistry industry. Machines and equipment for food processing represent a further key sector.

In this and other industrial sectors, machine constructors and hydraulic equipment engineers can now benefit from the fast and, at the same time, process-reliable, installation of clamps – particularly in horizontal or overhead positions. There is no longer any need to install weld plates, as a plastic spacer plate ensures the requisite distance between the body of the clamp and the substructure, enabling the use of standard accessories. The time-consuming reworking of welds is almost now completely a thing of the past. There is also very little material wastage, thanks to the shorter welding time and isolated application of heat. As the entire surface of the stud is connected to the tool, the joint is very strong.

The weld studs are available in 1.4301 (V2A) quality, with 1.4401 and 1.4404 (V4A) weld studs currently in the pipeline. The requisite assembly tool, consisting of a stud welding machine and a weld gun with a positioning tube, weld stud retainer and distance adapter, is already available. Users can therefore obtain the complete system from Stauff – clamps, stainless steel studs and assembly tool – your one-stop shop.