This new product in the portfolio will be proudly presented to the market just in time for the FachPack 2016 exhibition in Nuremburg. “It impresses not only through its outstanding hygienic standards, which come close to those of the pharmaceutical industry”, explains Wolfgang Merklein, Head of Food & Cosmetics at ViscoTec “but also through its simple implementation onto production lines with regard to dosing small quantities in the production of food and cosmetics. We are well prepared in terms of Industry 4.0 and individualization respectively, such as customized food.”

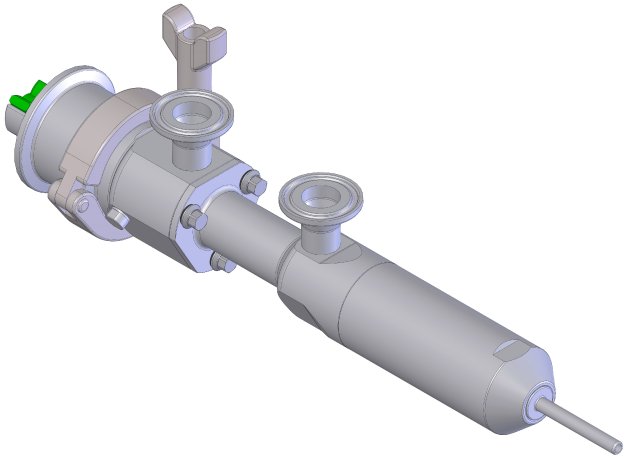

The ViscoTec Hygienic Dispenser is available in three different sizes, allowing for volumes of 0.35ml up to 5.1ml per revolution to be achieved. The smallest of dosage volumes can be perfectly dosed with a deviation of only +/- 1%. In addition to FDA-compliant components, and an EHEDG-compliant hygienic design, is the possibility of automatic cleaning via additional connection outlets. The cleaning medium is applied via the outlet in order to carry out automatic rinsing. Alternatively, the new dispensers can be disassembled quickly and cleaned manually.

As in all dosing systems from ViscoTec GmbH, the VHD uses the proven endless piston technology based on the use of eccentric screw technology. For the VHD, many characteristics have been optimized and specially enhanced for use in the food and cosmetics branch. Among other things, the interior of the dispenser has been analysed and redesigned: the goal being to avoid dead volume and thus prevent contamination through harmful micro-organisms. Tri-Clamp flanges with hygienic standards simplify the integration of VHDs into existing systems.

Thanks to the dosing geometry, a constant flow volume proportional to the rotary angle is always generated per rotation. The flow direction is reversed by changing the direction of rotation. The volume is thus clearly defined by the angular degree. This technique comprises of pressure-resistant, linear pump characteristics which make a clear statement about the relationship between revolution, time and delivery. This in turn leads to a guaranteed dosing accuracy of 1% (depending upon the medium) at the pump outlet, which is often well below this in practice. A further benefit of this technology lies in the resulting conveying chamber, the volume of which remains absolutely constant when in motion. This makes it possible to promote and fill solids-laden media and even lumpy products. Another advantage over other pump mechanisms: in over 95% of applications, filling and dosing valves can be eliminated, since a reverse flow at the end of dosing allows for a controlled breakage of the product thread and therefore prevents any dripping. Even the most difficult, highly viscous liquids can be reliably dosed or filled, without causing pulsation, incorrect dosages or excessive stress on the material.

With the VHD, ViscoTec has succeeded in reaching another unique milestone in the further development of the eccentric screw technology principle. Comprehensive quality management, its own research and development work, as well as collaborations with manufacturing companies and institutes guarantees the required quality of ViscoTec dosing systems and provides long service life even with difficult dosing applications.