The development of new products and production methods means that users are constantly faced with new requirements in terms of silicone's material properties. Meanwhile, the ongoing development of silicones is opening up new applications in the industry for future production methods. Because of these two technological drivers for chemical joins, this sector is currently experiencing rapid development.

As a result of their versatile material properties, two-component silicone rubbers are being used increasingly frequently in industrial applications. These silicones are long-chain polysiloxanes - mainly in a pourable to plastic form - that are vulcanised to an elastic rubber by addition or condensation curing. Their key features include high temperature resistance, good diffusion density, high chemical resistance and adjustable thermal conductivity. They are primarily used in the automotive and electronics industries, but also increasingly in the pharmaceutical and orthopaedics industry.

One very interesting product development involves two-component silicones in which the material hardness ("Shore hardness") in vulcanised form can be varied by regulating the mixing ratio. Uses of these silicones include applications in medical technology. In the manufacture of prosthetics, orthopaedic arch supports and pads, this type of silicone enables different hardness ranges to be established within a product.

To implement this control of the material hardness effectively in a manufacturing process, the dosing system used must guarantee easy adjustment of the mixing ratio synchronised with the hardness profile during material application.

In a dosing system with gear pumps, mixing ratios can be adjusted by a software-controlled change in the rotation speed of the gears, although this requires sophisticated control engineering. The dosing quantity produced does not have a linear relationship with the change in speed because of the back flow behaviour of this pump system. The actual delivery quantity must be measured by a volume meter and fed back to the system. This means that the dosing pumps adjust the actual dosing process after a delay. These variations in dosing become greater as the dosing quantities are reduced and the required dosing accuracy increases.

Because of the volumetric forced delivery principle they are based on, piston dosing systems do not require any sophisticated continuous adjustment, and operate with a reduced system complexity. However, in simple piston pump systems the fact that every variation in the mixing ratio can only be achieved by a hardware side system adjustment has a limiting effect. The solution involves adjusting the piston stroke using mechanical stops (bars) or by complete replacement of the dosing piston. Nevertheless, these hardware adjustments require modification work, costs for the replacement parts and significant system stoppages. A further disadvantage of piston dosing systems is the effectively limited production time caused by the necessity of re-filling the piston volume with the material. This cycle of dosing and piston filling required by the system means that only pulsed rather than continuous material delivery is possible. The time needed to refill the piston is extended as the material becomes increasingly viscous.

The best results - in terms of quality and cost - for using variable mixing ratios can be achieved with dosing systems that provide high accuracy in the component quantities to be applied, without cost-intensive control mechanisms, combined with time and cost saving software based configuration.

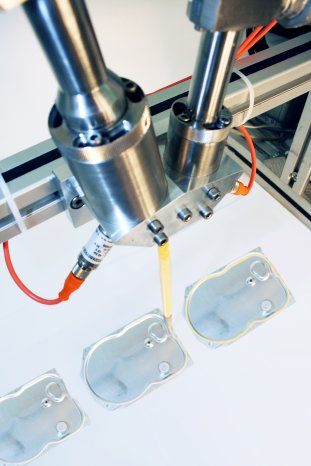

The endless piston principle used by ViscoTec has proved to be a very effective technology for flexible and precise adjustment of two-component mixing ratios within a dosing cycle. This method is based on a volumetric dosing principle that offers outstanding dosing accuracy even with fluctuating material viscosity. The interaction between the rotor and the stator produces enclosed chambers with identical volumes that also do not change during the dosing process. The special dosing geometry of the dispensers guarantees the pulsation free flow that is essential for precise control of mixing ratios. The material is conveyed from the intake to the delivery side of the pump and follows a uniform and continuous moving flow in one direction. Based on the configuration of two-component dosing systems, two dosing pumps are attached directly to a mixing head next to one another in a V arrangement. In this mixing head with optimised dead space, the A and B components of the silicone are fed to the static mixer by two separate channels. The special design of the outlet opening extends the separate feed channel for the components into the static mixing pipe and reliably prevents a direct curing reaction in the mixing head itself. The direct combination of the dosing pumps at the mixing head and the use of short dosing distances after the pump outlets eliminate dosing inaccuracies that can otherwise occur due to uncontrollable pressure profiles in long conveying distances. The specified mixing ratios can be achieved with excellent accuracy using the system construction described.

Based on the achievable dosing accuracy of the system, dynamic changes to the mixing ratio when applying material is achieved by variable control of the individual delivery quantity for each material channel. The eccentric pump technology used works on a strict volumetric principle. Each pump revolution always doses a fixed, defined volume of material, with a defined speed in revolutions per unit of time allowing a delivery quantity in ml per unit of time to be set. There is a linear correspondence between the dispenser speed and the dosing quantity, i.e. doubling the speed results in double the delivery volume with no delay. This volumetric accuracy is achieved on the systems with outstanding reliability and no pulsation even with fluctuating viscosity values. On the two-component dosing system described, the delivery quantity per channel depends on the required mixing ratio for the two-component silicone. The motor speed of the dispenser drives is controlled by an analogue signal. The delivery quantity is provided at the pump outlet in the exact volume required and directly linear to the set analogue control signal. Because of this functional principle, the system provides the technical capability of continuously changing the dosing quantity per unit of time at any point in the dosing process and allows quantity profiles to be used. This means that variable mixing ratios for the materials delivery to be used.

The control concept for the two-component dosing system provides two interfaces. The drive units can be actuated either by external signal paths from a higher level controller in an automation system or by the two-component dosing controller specially developed by ViscoTec.

On the ViscoTec controller, all basic parameters for the process - such as mixing ratio, dosing speed and dosing quantity - are preset and calibration is performed. The integrated recipe management function enables different mixing ratios and thus product properties to be preset, stored and activated by just a few clicks on the touch panel.

As well as setting these basic parameters such as dosing quantity, dosing speed and mixing ratio, the ViscoTec controller provides an extensive range of adjustable process parameters that support fully automatic production and ensure a stable product quality. The dosing controller includes an option for specifying and monitoring the dispenser intake and dosing pressures. If the limits defined by the user are exceeded, a visual indication appears on the display and an electric signal is transmitted to external devices. Additional parameters for specifying the material pot life and for adjusting the time to next rinse and a rinse counter are also available. If at least x times the filling volume of the static mixer has been dosed within the set pot life, the system generates an error message. This ensures that no material that is already reacting is used and prevents curing in the static mixer. Using the time to next rinse parameter allows the controller to initiate a rinse before the pot life has elapsed. By sending a signal to an external controller, the handling system can move to a defined axis position for the rinse. For example, to prevent excessive consumption of silicone material for rinses during a significant system stoppage, a maximum number of rinses - i.e. a limit on the number of rinses to be carried out - can be set. Once this maximum quantity has been reached, the controller generates an error message and supports the operating personnel in proper system management.

The endless piston principle from ViscoTec is also used in material extraction and treatment systems in addition to its use in two-component dosing systems. The material supply routes for two-component systems are provided by parallel channels for the A and B component. With the technology described here, ViscoTec can guarantee uniform and high quality processing of silicones all the way through the entire procedure, from emptying of the material through to the dosing process itself.

The application engineers from ViscoTec Pumpen- u. Dosiertechnik GmbH would be glad to provide you with assistance and advice on all matters concerning dosing and preparation of the materials discussed above.