T24 is a material which plays a decisive role in current construction projects, but unexpected problems have arisen during handling. In his lecture Frank Neumann, Head of Department at RWE Technology in Essen, Germany, will describe the damages incurred and report on test results and the conclusions drawn about the origin and nature of the damages.

Certain components require specific manufacturing conditions, which must be allowed for by constructing engineers. Erik Solomonsson, Distribution Manager of Sandvik Powdermet AB in Surahammar, Sweden will give a lecture on hot isostatic produced components for power plants. During this process complex components can be produced on a powder-metallurgy basis, thus avoiding elaborate and complicated welded structures.

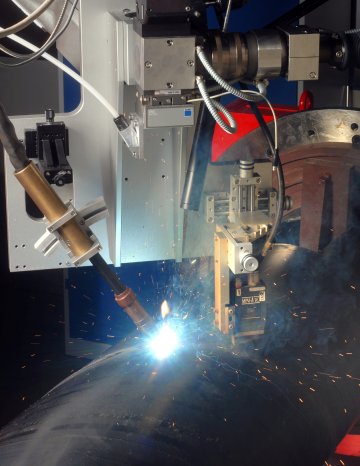

Experts from the European Technology Development in Surrey, Great Britain, will describe how they repair thick-walled components of P91 martensitic steel and prevent crack formation. Furthermore they will explain how temperatures are controlled in the thermal treatment of the P92 alloy after welding. During this process thermodynamic modelling plays a major role.

The international conference addresses world-wide specialists and managers of operating plants, manufacturers and suppliers as well as consulting engineers, technical quality inspectors, and research personnel.

Further information, registration and programme at www.vdi.de/... or via VDI Wissensforum Kundenzentrum, P.O. Box 10 11 39, 40002 Duesseldorf, E-mail: wissensforum@vdi.de, Telephone: +49 (0) 211 62 14-2 01, Telefax: -1 54.