The global market leader for integrated cable and connection technology solutions provides its customers with a new fibre optic cable configurator. This enables users to quickly and easily put together the appropriate fibre optic cable assembly. After selecting the required components, the assembly can be ordered from LAPP at the push of a button.

“Customers value our expertise in assembly of robust fibre optic cables for tough industrial applications. We specialise in this area, allowing our customers to concentrate on what they are best at: their core business”, says Guido Ege, Head of Product Management and Product Development at U.I. Lapp GmbH.

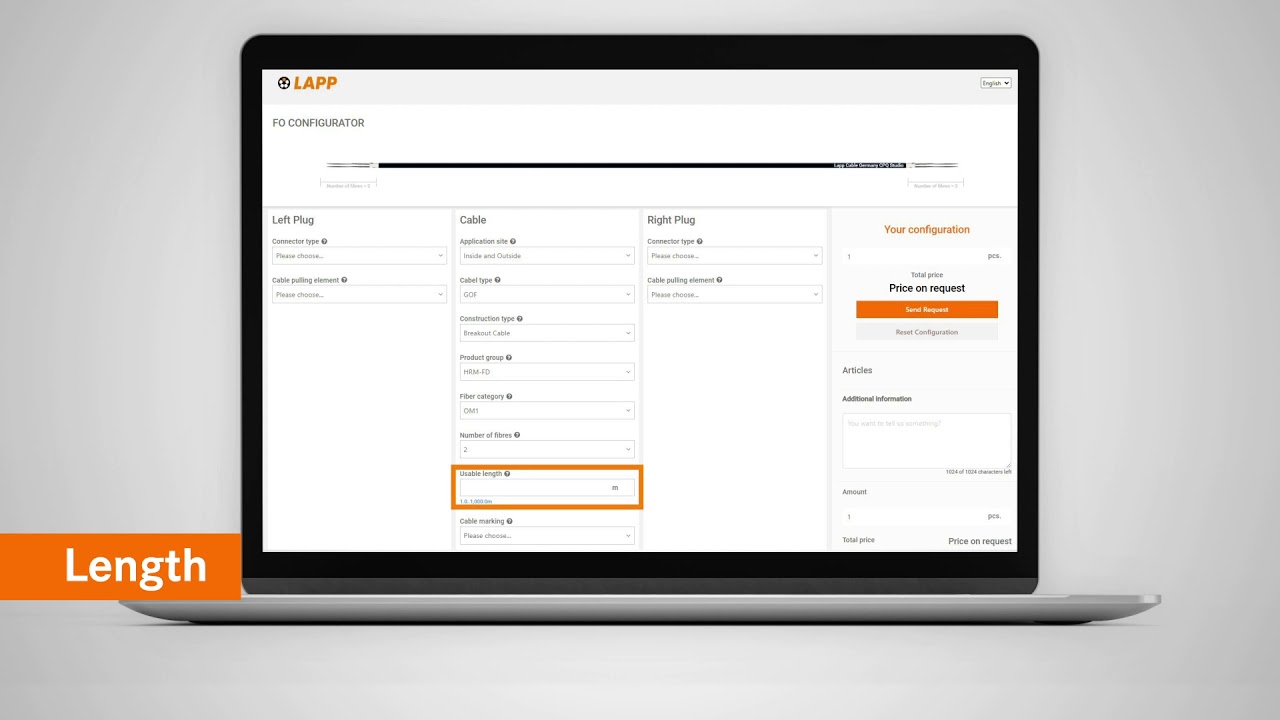

LAPP produces the assemblies for glass fibre cables and fibre optic cables according to customers’ exact requirements with cables based on standard fibre types (glass, POF, PCF). The configurator first shows the products based on different application areas. For example, indoors or outdoors or with various combinations of glass fibres and plastic fibres, such as polymer optical fibres (POF), polymer sheathed optical fibres (PCF) or glass fibres (GOF).

The LAPP product range includes various cable types such as simplex and duplex cables or loose tube cables, breakout cables and space-saving mini-breakout cables. Glass fibre cables and fibre optic cables such as HUN, HQN1500, HQW3000, HQW-Plus3000, Fire, TORSION, HUW1500, HVN, HRH, HDH and HDM are available under the brand names HITRONIC®. The fibre optic cables are available as single-mode cables (OS - Optical Fibre Singlemode - OS1 and OS2) and multimode cables (OM - Optical Fibre Multimode - OM1, OM2, OM3 or OM4).

The user only needs to select the necessary transmission rate or the fibre type and the preferred connector (FC connector, ST connector, SC connector, LC connector, E-2000 connector etc.) and the configuration is complete. A digital sales advisor is available to help prevent errors during the selection process and also creates an immediate personal quotation.

“We test all glass fibre assemblies. Customers receive a test report for each assembly on delivery”, says Norbert Strohmaier, who is responsible for configurations at LAPP, and emphasises: “Carefully selected components, continuous production and quality monitoring and a higher connection quality make applications more reliable.”

Link to the configurator: www.lappkabel.com/fo-configurator