"In purely mathematical terms, TÜV Rheinland can test around 30,000 modules per year with the Mobile Solar Lab. This sample volume would correspond to a cumulative connected load of around 1 gigawatt peak (GWp) or more than 1 million PV modules," explains Roman Brück, solar expert from TÜV Rheinland.

Laboratory on four wheels

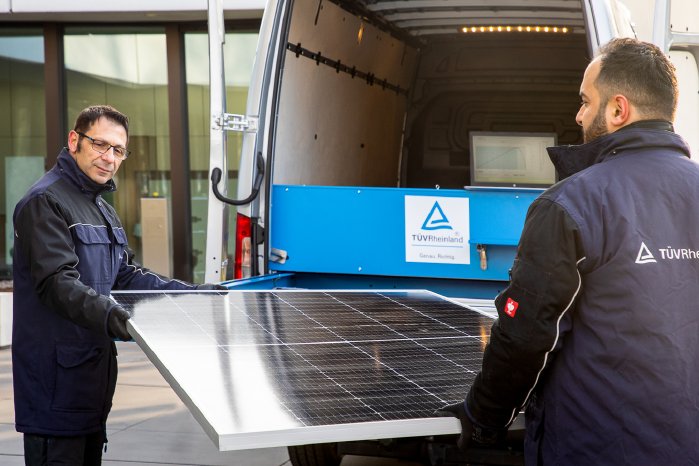

The mobile PV laboratory is built into a commercial vehicle. It has all the technical equipment needed for batch measurements before PV modules are installed. The TÜV Rheinland experts can use it to test up to 150 modules per day. It is not unusual for a sample to consist of several hundred to a thousand modules. With conventional testing methods - including disassembly and transport to a stationary laboratory - this would take several weeks, instead of a few days with the mobile laboratory. As a result, the new testing method also pays dividends in terms of accelerating the energy transition.

Stationary laboratories still in demand

This does not mean that stationary laboratories will become obsolete in the future. "Many preliminary tests require special equipment such as climate chambers, hail machines or mechanical load test stands," adds Thomas Brück of TÜV Rheinland. However, "in the area of randomised batch testing, we assume that the mobile PV laboratory concept will be the model of the future".

Further information at: www.tuv.com/solar