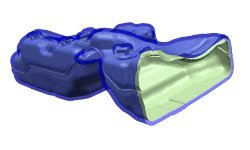

Generation of offset models – DMU.Offset With this module, models for digital prototype construction can be enlarged or enveloped by a value which can be individually defined. This function can, for example, be practically applied in the testing of the geometric behavior when the application of material coating is to be simulated on sheet metal. A further example for the employment of DMU.Offset is the increase of the density of complete assemblies, such as engines. In this way clearance spaces to the environment, which are necessary for the engine marriage, can be taken into account.

New data formats can be utilized With the Release 3.1, the completely open architecture of the Teraport DMU Toolkit has been further expanded. It is already possible to process numerous native and neutral data formats. It is now also possible to read JT files (DMU.JTReader) and CATIA CATProducts (DMU.CATReader). Hence the scope of application of the Teraport calculation tools can be utilized even more easily, particularly in heterogeneous CAD and PDM environments.

Standard workflows as a generic solution As an additional feature, particularly for smaller companies, generic packages for standardized solutions are available as from Release 3.1. This facilitates a more rapid and inexpensive introduction to the DMU Toolkit. Profiles have been drawn up for seven different workflows, as, for example, for the automatic assembly / disassembly simulation with Catia or Pro/E data, which can be employed immediately without any need for customization. In accordance with the clients’ requirements, two alternative approaches to solutions are now offered. On the one hand the standardized solution with the generic workflows, and on the other, the individual DMU solutions which have already proven themselves with their high degree of integration into the client processes and a distinctly broader range of functions.