Currently several hundred printing automations are in use in multi-shift manufacturing plants using the simple tampon printing process.

Advantage:

Sturdy cliché cylinders made of ceramic or hardened steel, Service Life of ceramic clichés over 100 million prints

- Laser engraved image guarantees registration

- Variable gravure depths for highest standards

- Fast setup time and simple manipulation

- Speedy adjustable doctor blade

- Clean environment not necessary

- Dust disappears within the ink

- Uneven surfaces are no problem

- Injection points on die casting are over-printed

- Concave and convex surfaces are printed

- Inexpensive solvent-based inks for PP- and PE material

- U.V. lamps not necessary

The Offset Procedure:

During the last 10 years the Dry Offset Procedure was greatly improved for the bottle closure decoration sector, but the following points need to be observed:

- Printing surface needs to be even.

Why? With an uneven surface the print blanket will be squished and this results in an irregular print image.

- A clean and dust-free surface is a requirement.

Why? If the to be printed product is contaminated; the dirt is transferred from the print blanket onto the cliché and the inking unit and therefore deteriorates the print result.

- Setup: For a good print result the cliché has to be carefully mounted.

- The colouration is very sensitive as otherwise the print result is not satisfactory.

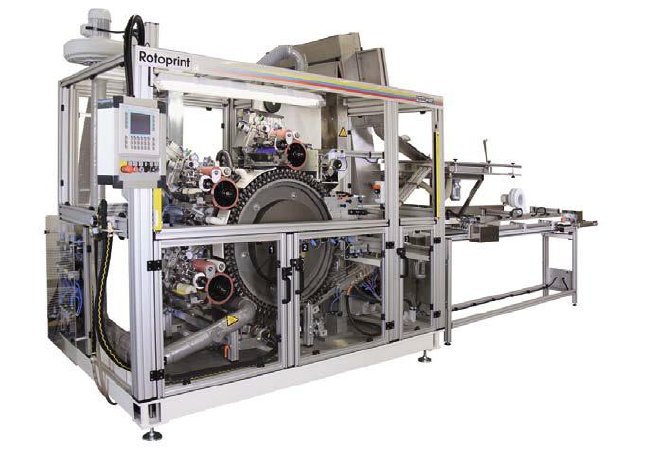

After several new inventions worldwide, in 1981 the first rotary tampon printing machine was built and sold. The rotary print applies to cylindrical and flat components or sectional surfaces. Currently the rotary printing process is well established mainly in the Closure Cap Industry.

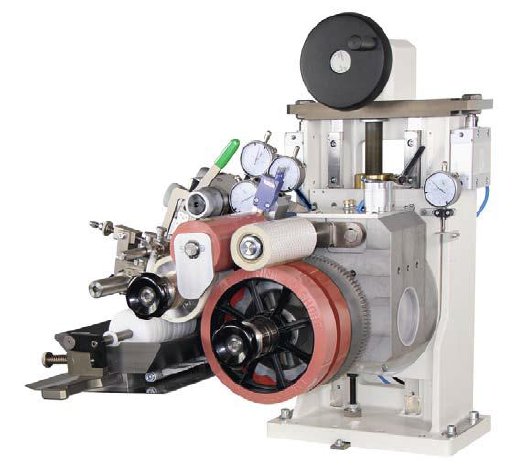

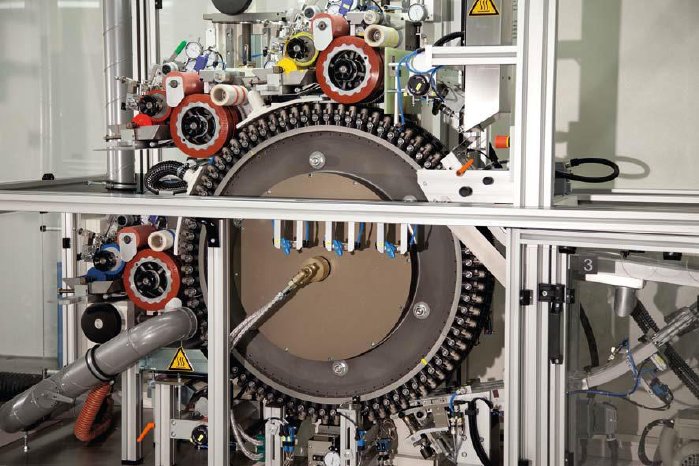

To offer the market and the product design further enhanced decorating and marking possibilities, TAMPOPRINT® developed the rotary printing system "RTI 21-150". The new "RTI 21-150" is build into every "Continua" and "Rotoprint" machine. Additionally a new tampon printing roller "RP" with a plastic wheel was developed for best price/cost effectiveness.

The accuracy of registration depends significantly on the heat factor within the machine technique, as well as the ambient temperature. To offset this, our "Rotoprint" has water cooling at the wheel as an option; this is especially beneficial in non-air conditioned facilities.

Apart from ink, the transfer of other media, such as lubricants and pastes is also possible.

This year interested parties can inspect the rotary printing unit "RTI 21-150" in its function installed into the fully-automated "Rotoprint". This proven automation is specially designed for the marking of plastic closure caps.

Visit us at the FAKUMA 2012 in Friedrichshafen, Hall A1, Booth 1233. Here you will receive expert advice. Technical details or a personal appointment can be requested by emailing to mailto:messe@tampoprint.de. At all times we offer live demonstrations of our machines in progress. We invite you for a personal visit to our company headquarters or to co-ordinate a video conference on a desired appointment date.

Trademarks of TAMPOPRINT® AG: ALFALAS®, TAMPOPRINT®, ClipLock®, record®