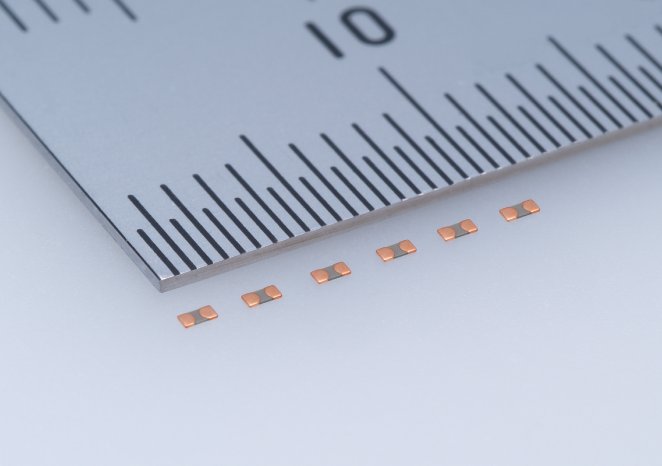

Taiyo Yuden’s portfolio of high-value, low-profile multilayer ceramic capacitors has been expanded to include capacitors only 0.15 to 0.33mm thick, demonstrating the company's strong commitment to providing superior products in this field.

Mass production of the product will begin in November 2009 at the company’s Tamamura Plant in Gunma Prefecture, Japan at an output pace of 1 million units per month. The price for samples is 4 yen per unit.

Technology Background

Smaller, slimmer mobile phones and smartphones with high-performance specs are becoming increasingly popular. The latest devices have larger LCD screens as well as more and better functions such as Internet connectivity, audio and visual entertainment, and high-quality photographic capabilities. In order to keep devices from getting bigger when all this new functionality is added, electronic components such as high value multilayer ceramic capacitors for IC power lines are being miniaturized. Demand continues to grow for low-profile electronic components, including capacitors, for use inside the printed circuit boards of modules, or substrates made using embedded components technology. By incorporating these low-profile components, a more efficient component layout can be attained, which in turn leads to more advanced functionality in devices in ever smaller, slimmer dimensions.

Since the release of its nickel-electrode high-value multilayer ceramic capacitor in 1984, Taiyo Yuden has worked to create ever more compact and higher value capacitors by developing material and thin layer technologies for multilayer ceramic capacitors. Those technologies were employed in the new low-profile multilayer ceramic capacitors, too, to achieve high capacitance values up to 0.22?F in a size of just 1.0 x 0.5 mm (EIA 0402), with a maximum height of only 0.15 mm. External electrodes are applied with copper plating to achieve optimum mountability on component-embedded substrates.