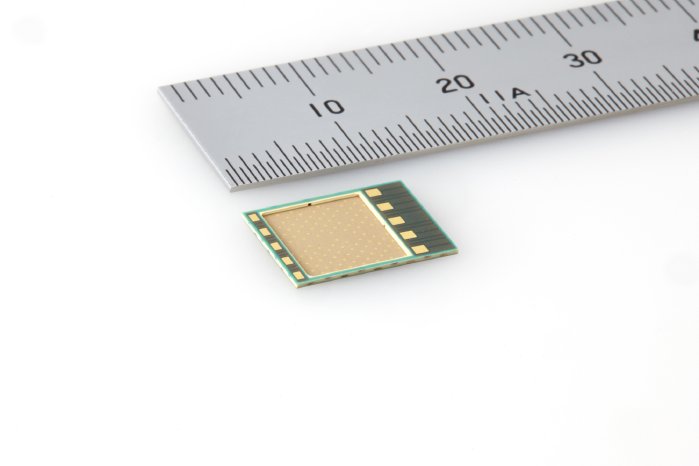

This product is an embedded-parts multilayer wiring substrate for camera modules that are mounted in compact mobile devices such as smartphones and wearable devices. In today’s rapidly advancing markets the requirements for substrates to possess flatness and rigidity is ever increasing. Additional requirements are noise immunity needed to address less distortion and prevention of entry noise. These characteristics are critical to support high definition features and the narrowing of the pitch of pixels in camera modules with an increasing number of pixels. TAIYO YUDEN has developed a cavity formation technology as a resolution to the high accurate flatness while retaining the characteristic noise immunity and high rigidity of the embedded-parts multilayer wiring substrate “EOMIN™”. Thinner camera modules can be realized by mounting an image sensor in the cavity.

Technology Background

In today’s market which is driven by the need for continued improvements in functionality and performance, such as a higher number of pixels and camera-shake correction functions, there is a strong demand for small-size and thin camera modules mounted in compact mobile device for products such as smartphones and wearable devices. Camera modules are required to be even thinner so that they can be mounted at the back of the panel in devices that use a panel with a narrow frame in order to realize a larger screen size of the display panel while retaining a compact casing. The increase in the number of pixels to as many as 12 million has unfavorably increased the size of the image sensor and the overall thickness of camera modules. To address this market need, TAIYO YUDEN has developed a technology that enables the formation of a cavity in the copper core embedded-parts multilayer wiring substrate “EOMIN™”, which has exhibited several results for camera modules. By mounting an image sensor in the cavity, the overall module has been made thinner and more compact while retaining the characteristics of the embedded-parts multilayer wiring substrate “EOMIN™”.

We will continue to produce multifunctional modules while actively promoting a further reduction in the thickness of copper core embedded-parts multilayer wiring substrate “EOMIN™”, and contribute to the improved functionality of devices and reductions in their size and thickness.

*“EOMIN” is a registered trademark or trademark of TAIYO YUDEN CO., LTD. used both for Japan and other countries.

Applications

For camera modules mounted in compact mobile devices such as smartphones and wearable devices.