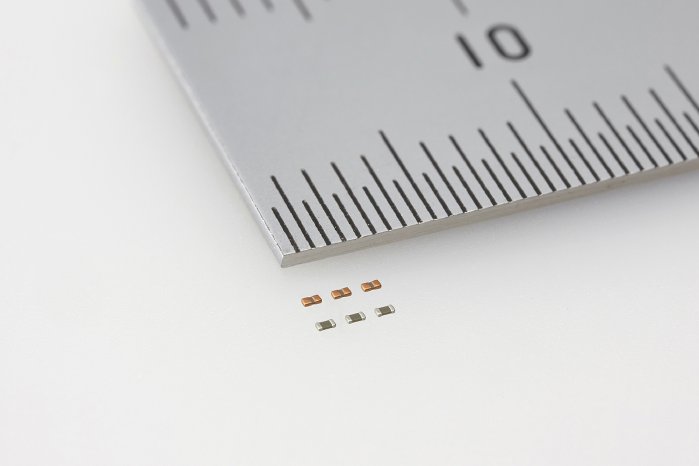

These multilayer ceramic capacitors are used for the decoupling of IC power supply lines in small and thin devices, such as smartphones and wearable devices, and as various modules characterized by the copper core embedded-parts multilayer wiring substrate, “EOMIN™”. TAIYO YUDEN has made full use of the material technology, thin film technology, and multilayer technology of its multilayer ceramic capacitors that exhibit high performance while realizing

a large capacitance up to 0.22 μF. This capacitance level is the highest in the industry for the same size component. The conventional product lineup of the low-profile multilayer ceramic capacitor is a height of 0.15 mm including up to the EIA 0402 size. TAIYO YUDEN has further reduced the size up to EIA 0201, a reduction of 64% in the mounting area while retaining the same thickness. And, as is the case with the EIA 0402 size, copper plating that is suitable for mounting the capacitors on embedded-parts multilayer substrates is performed in the “JMC063 BJ224MH” and “JMC063 BJ104MH” capacitors.

Production of these multilayer ceramic capacitors will commence at the company’s Tamamura plant in Gunma prefecture, Japan, from January 2014 onward at a production rate of 10 million units per month.

Technology Background

Multilayer ceramic capacitors are placed near an IC device mounted in a smartphone and other such application for the purpose of decoupling. This controls outside noise and prevents the noise from entering in to the IC. Similarly, the noise generated from the IC does not affect the other ICs. However,

due to a reduction in the size of devices and the improvement in functionality, the mounting area of parts has been reduced. Rather than the already-known methods of mounting the multilayer ceramic capacitors on the substrate, there is a need to implement high-density mounting, which includes mounting inside or at the back of the IC package and the use of the embedded-parts multilayer substrate technology in which the capacitor is embedded into the substrate.

To address this market need, TAIYO YUDEN has been able to reduce the size of its multilayer ceramic capacitors from EIA 0402 to EIA 0201 by further improving its material technology, thin film technology, and multilayer technology while retaining the thickness of the conventional TAIYO YUDEN products. We will continue to actively promote the product development of low-profile multilayer ceramic capacitors to realize a thinner profile and higher capacitance.

*“EOMIN” is a registered trademark or trademark of TAIYO YUDEN CO., LTD. used both in Japan and other countries.

Applications

For decoupling of IC power supply lines in devices that are required to be small and thin, such as smartphones and wearable devices, as well as various modules typified by the copper core embedded-parts multilayer wiring substrate “EOMIN™”.