In particular, the dimensions and the weight of truck treads are in a range where the manual handling is linked with a heavy burden on the human body. This inevitably results in an improper handling of the treads in order to cover the workload and, as a consequence, lateral and longitudinal deformations of the treads occur at the expense of the quality of the finished product. Increasing cycle outputs on the tire building machines also force the tire manufacturers to think about an automatization of the tread loading process.

Increase in quality by means of an automated tread handling

SYSTRAPLAN, provider of automatic tread booking systems, use their vast experience in the handling of treads to drive the development on the loading process for tire building machines. However, to achieve this, some problems had to be solved during the development of the new system.

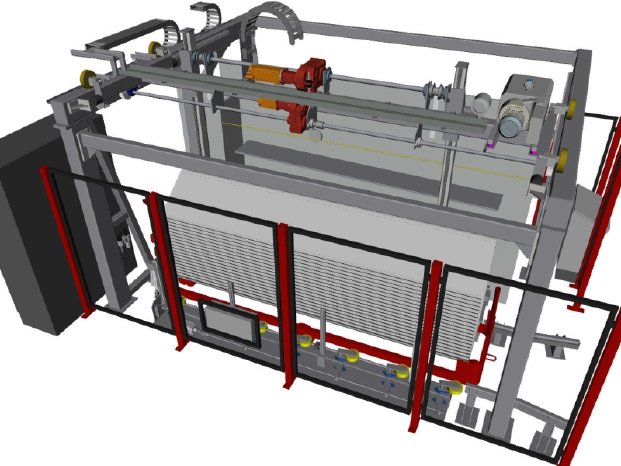

Space saving gantry system

Due to the reduced space around the truck building machines it was decided to choose a compact and space-saving gantry system with a movable suction frame. This frame moves up and down on the gantry and picks single treads from the leaf truck side by means of an automatic adjustable “suction-carpet”. The suction frame is designed in such a way that it moves into the leaf trucks’ opened flap. All suction cups are arranged in grouped sections, individually controllable and in longitudinal direction movable to cover and suck in the various different tread dimensions.

Automatic detection of tread position

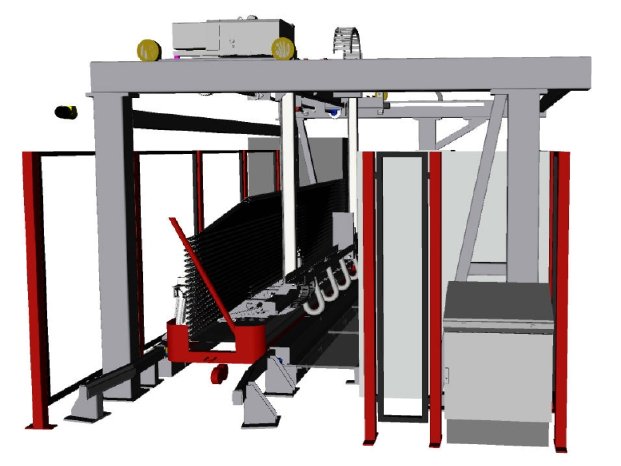

Prior to positioning and locking of the filled leaf truck at a particular unloading position underneath the gantry through an automatic leaf truck transport, the leaf truck is manually conveyed in by the operator.

The treads must be placed on the leaf truck’s side within a determined tolerance range. It is appropriate therefore to load the leaf trucks by means of an automated leaf truck loading system. This is the best way that the positioning of the treads is kept within the stipulated tolerances.

A special sensor attached to the suction frame is automatically detecting the exact position of the tread whilst it is fed in and prior to the positioning of the suction frame and the collection of the tread.

Opening of leaf truck flaps

The opening of the leaf truck sides can be carried out manually by the operator as well as automatically by means of a separate device to flip open the sides, as they have already been known from the SYSTRAPLAN automatic leaf truck loading systems.

After the gantry has moved into the parking position the operator has the possibility to enter the area underneath the gantry to flap the empty side upwards.

Removing treads

The focal point of the system is the detachment of the treads from the flaps of the leaf truck. While the cut surfaces of the treads are sprayed at the end of the extrusion line, redundant material often adheres – sometimes stubbornly – to the flaps of the leaf truck. It is particularly important to optimize the process right at the beginning to the greatest possible extend to prevent the treads from sticking to the flaps when removing.

The suction frame has down-holders for a safe tread removal from the flaps. These down-holders hold the leaf in place during the suction procedure. The time-delayed connection of the individual suction rows accomplishes also a “peel-off” effect when removing the treads.

The maximum applicable suction performance to release the treads off the leaf can easily be adjusted and is eventually depending on the surface and condition of the treads. Markings on the treads’ surface caused by an excessive high vacuum should be avoided. Treads with a too high adhesion, on the other hand, might do not come automatically loose. In this extreme event the operator needs to take supporting action.

Feeding of tire building machine

The tread removed from the leaf truck are then positioned through the gantry by means of the suction frame on the feed roller conveyor of the tire building machine.

The treads can optionally be placed on a flipping unit that subsequently places the turned treads on the feed roller conveyor of the tire building machine.

Next to the standard exchange of signals, the systems allows a data exchange relating to the tread basis data with the help of a direct link between automatic loading system and tire building machine.