Growing regulations restrict hazardous substances in manufacturing worldwide. Electronics/electrical manufacturers, testing laboratories, as well as makers of packaging, plastics, toys, cosmetics, and others, must make sure that products comply with these regulations and that substances such as toxic heavy metals are not present in consumer goods, raw materials or additives at concentration levels above regulation limits.

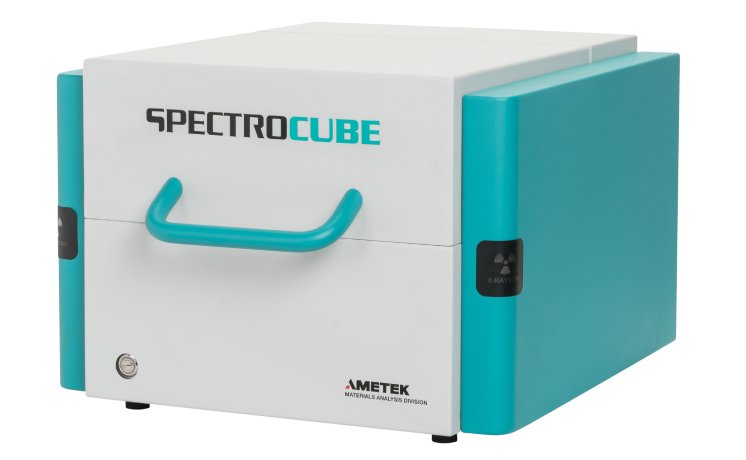

SPECTROCUBE ED-XRF determines exactly what elements are present in a given sample, and at what concentration levels. The new analyzer incorporates state-of-the-art nondestructive ED-XRF detector technology, including high-resolution and high-count rate, to deliver short measurement intervals, effortless workflow via intuitive software, and low downtime.

SPECTROCUBE enables a fast, smooth workflow, even for minimally trained users, to ensure an unparalleled ease of use. The sample analysis is performed in three quick and easy steps, with the intuitive software presenting the relevant information on a single screen. Its compact footprint fits tight benchtop spaces yet accommodates a wide range of tiny to large sample sizes.

Featuring exceptional speed and performance, SPECTROCUBE ED-XRF provides high precision for a wide range of concentration levels, plus testing times as low as 60 seconds that enable a throughput of hundreds of samples per day. On samples large or small, the instrument can analyze an area down to a spot size of 0.2 mm that is among the industry’s smallest spot sizes.

Designed for future-proof flexibility, SPECTROCUBE meets the full spectrum of regulations, handling real-world compliance analyses — today and tomorrow. With the latest high-resolution silicon drift detector (SDD) and an ultra-high-count rate, SPECTROCUBE handles trace elements with ease. At the same measurement time as previous-generation models, SPECTROCUBE delivers up to three-times higher intensities for significantly improved precision. It even screens the full spectrum for all relevant elements with every analysis. Importantly, as the lists of restricted materials continue to grow, users can easily activate new configurations to handle additional matrices, elements, and compounds in the future via simple software updates.

Constructed with user-tested, top-grade components for continuous use in demanding, high-throughput quality control operations, SPECTROCUBE ED-XRF delivers rugged reliability paired with low operating and maintenance costs over a long, trouble-free service life.

SPECTRO helps ensure uninterrupted performance and maximum ROI via unmatched AMECARE services. Machine-to-machine (M2M) support allows proactive alerts, backed up by an on-request PC connection with a remote SPECTRO service expert.

The new SPECTROCUBE analyzer is available immediately from SPECTRO Analytical Instruments. For more information, download “Introducing SPECTROCUBE — ED-XRF Spectrometer for Compliance Screening” at https://www.spectro.com/spectrocube, or email spectro.info@ametek.com.