Since Sonderhoff’s market start in China beginning of 2009 their business developed very well. Sonderhoff (Suzhou) Sealing Systems is responsible for the exclusive sales and distribution of all products of Sonderhoff in China. In order to become more independent from imports, polyurethane material production will start at their new, greater location in the Singapore Industrial Park (SIP) in Suzhou at spring this year. The new material production from Sonderhoff in China and the new machines for expanding the contract manufacturing of Chinese customers’ parts is an investment in the future for the company’s further growth in China.

At the new location contract manufacturing services for foam gasket, gluing and potting applications is also available for customers who do not have their own dispensing machines. They are offered individual sampling of prototypes, as well as pilot application processes or small batches up to serial production.

At the Chinaplas Sonderhoff will focus especially on the advantages of the Formed In-Place (Foam) Gasket dispensing technology for foam sealing, gluing and potting which has become increasingly popular in China: - automated process for precise dispensing of 2D or 3D components in a great variety of shapes using linear and/or 6-axis handling robots, - adaptable to different production processes; high efficiency, especially in large quantities, - potential cost savings because raw materials can be utilized up to almost 100% and less personnel through a higher degree of automation, - foam sealing accurate to the parts’ contour with consistently high quality, - also suitable for the component application of 2-component adhesives or potting material. Sonderhoff is a one-stop shop for the plastics and metal processing companies. They have the choice of more than 1,000 material formulations for various applications, for instance, switch board enclosures, electronics, automotive, air condition, filters, lighting, photovoltaic, packaging or household appliances. They can rely on the corresponding dispensing systems from Sonderhoff for the automated application on industrial parts as well as its process know-how, multi-patented knowledge and 55 years of our experience. In accordance with it, the Sonderhoff System combines chemical and technical competence with creative engineering know-how and a comprehensive service.

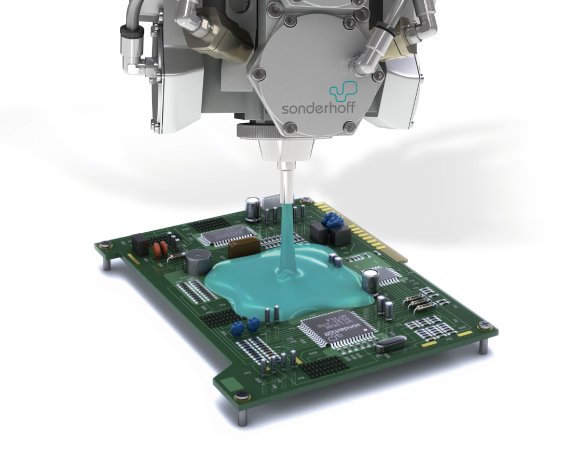

The 2-/multi-component dispensing systems DM 402/403/DM404 are very accurate and low in maintenance. They are available from stand-alone mixing and dosing machines or dispensing cells to tailor-made automation concepts for fully automated production lines of foam sealing, gluing and potting. The systems are specially designed for precise processing of fast curing as well as liquid, medium to high viscose media such as polyurethane, silicone, epoxy resins and other polymer reaction substances.

For the sealing of lighting housings, automotive parts, electrical enclosures, industrial filters and others the polyurethane foam seal systems FERMAPOR®K31from Sonderhoff are distinguished by: - resistance to environmental effects such moisture, dust and temperature (-40°C to +100°C), - protection classes up to IP68 / NEMA 12, - a low water absorption and flame retardancy up to UL-94 HF-1, - easy compensation of large part tolerances, - good adhesion to different types of surfaces, - tack-free time of 2-20 min. at room temperature and a cost-efficient manufacturing process with FIPFG dosing technology.

The polyurethane potting systems FERMADUR®, available transparent, opaque or in different colors, are distinguished by: - resistance to environmental effects such moisture, dust and temperature (-40°C to +100°C), - protection classes up to IP69 / NEMA 4 or flame retardancy up to UL-94 V-0, - good thermal conductivity and dielectric properties, - good adhesion to different types of surfaces, - flow ability, reactivity, hardness classification, as well as thin fluid to a thick paste viscosity, - low shrinkage, low surface tension and high impact strength and available

The polyurethane potting systems FERMADUR® are applied in various application areas, from surface coating and protection against environmental effects, to encapsulating electronic components, e.g. the potting of automotive connector plugs, relays, transformers, condensers, sensors and others.

In a nut shell, Sonderhoff (Suzhou) Sealing Systems Co. Ltd has established itself in the Chinese market as a specialist for automated 2-/multi-component mixing and dosing systems for foam sealing, gluing and potting and as a manufacturer of these materials, reliable for individual solutions according to the customers’ requirements. The team of specialists is prepared for technical services, machine maintenance, spare parts supply for existing machines as well as training programs for the customers.