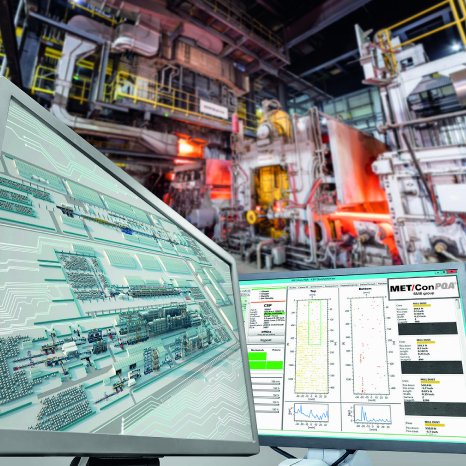

The new PQA® Product Quality Analyzer from MET/Con is going to be implemented at Emmenbrücke as a pilot for a group-wide Industry 4.0 initiative. With this quality management system, Swiss Steel aims to further enhance the quality level along the entire production chain, achieve more stability in the production process, further improve on-time delivery performance and optimize the company’s competetiveness in the long run.

MET/Con, a company of SMS group, was commissioned to supply an integrated IT solution operating on knowledge-based expert rules. Use will be made of an advanced software and database solution from Aachen-based QuinLogic, an SMS group company. Solutions based on this approach have been successfully implemented at selected flat steel producers with a great variety of downstream processes.

The PQA® system carries out online analyses of process, production and quality data from steelmaking, casting and rolling, right down to the drawing processes. The PQA® expert quality rules, which can be freely configured and fed with specific knowhow, take into account customer- and order-specific information in the quality assessment process and for the block-or-release decisions for the next downstream processing step.

The modular software consists of a LogicDesigner for flexible rule adaptation, a quality assessment module and web-based reporting. The centerpiece of the quality management system is the DataCorrelator software module, which covers latest features such as “Big Data” analyses and artificial intelligence (AI). Various intelligent mathematical evaluation methods, including pattern recognition options, identify and indicate correlations that can be directly used for process optimization.

With this project, Swiss Steel, Steeltec and MET/Con want to set a milestone showing how the performance, efficiency and quality level of the mill can be further improved by gaining total process and production transparency.