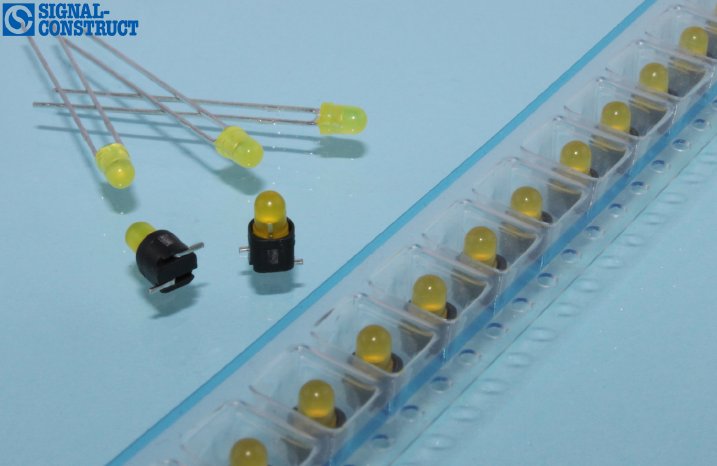

With our machine park we can process radial components such as 3 or 5mm LEDs, but also bipolar LEDs, IR or photodiodes, up to the LED / holder combination in the blister tape for automatic assembly.

The processing of LEDs has been a focus of Signal-Construct for more than 40 years.

What started as pre-assembly for our own products is now an independent and growing area, which still makes us one of the most sought-after LED manufacturers in Europe.

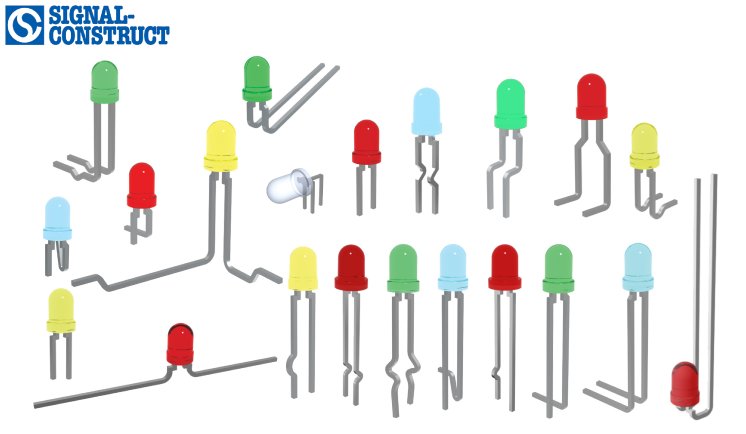

Leaded LEDs are processed according to customer-specific requirements on machines developed in-house. Through the use of special sorting and conveying devices, not only reeled components but also inexpensive bulk goods can be processed gently.

Up to 6 processing steps are currently possible in one tool:

- Bending the pins according to the drawing, even in different levels,

- Cutting the pins to size, marking the polarity with different lengths,

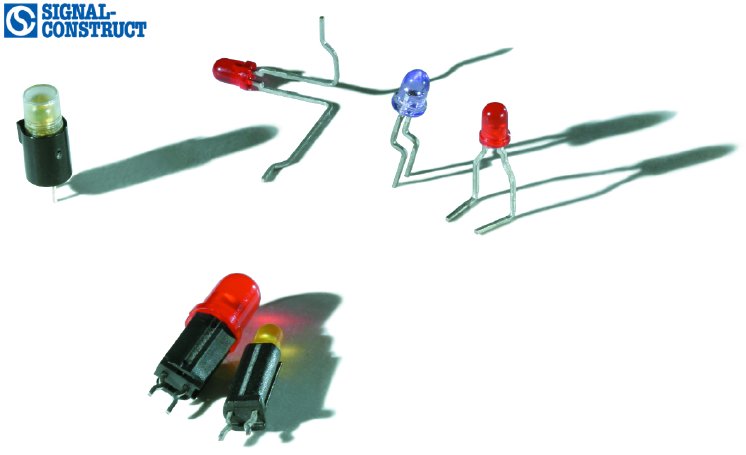

- Attaching retaining beads, which fix the LED securely in the board,

- Equipping the LED in various spacers.

- Polarity (also bipolar LED)

- Forward current

- Reverse voltage

The pre-assembled LEDs can be processed manually or automatically without further preparation and rework.

The retaining bead enables the circuit board to be handled without problems until it is soldered.

An additional advantage: Your ERP and logistics are not burdened with semi-finished parts. You only buy what you actually need.

Another highlight is the reworking of wired 3mm LEDs to SMD components:

In order to make the advantages of the 3mm LED (narrow beam angle!) available for the automated assembly of SMD technology, Signal-Construct processes the LEDs accordingly and winds them up on paper or blister tapes. This creates new, technically and economically convincing design and application options, especially for the combination with light guides.

Are you looking for solutions for your LED application? Contact us!