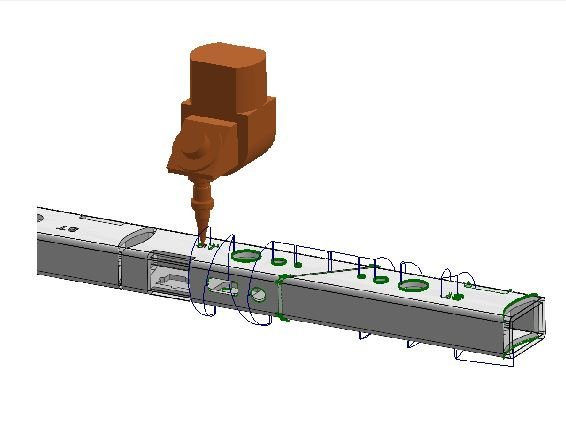

A complete tube and pipe cutting software, SigmaTUBE supports round, square, rectangular, or triangular tube/pipe. In addition structural material such as I-beams, H-beams, C-channel, and angle iron are supported. Custom programs are available to fully maximize the advanced features of Mazak FabriGear, Trumpf, BLM, Bystronic, Amada, and other 3D tube and pipe cutting laser machines.

Key features include:

- Flexibility allows multiple cutting machines to be driven with a single solution

- Supports multiple assembly model configurations

- Simple model refresh provides updated design revisions

- Cutting technology table sets cutting condition parameters

- Operates seamlessly within the SolidWorks® environment

SigmaTEK Product Manager, James Lindsey comments:

"Tube and pipe cutting has traditionally lagged in terms of sophisticated nesting; this all changes with the release of SigmaTUBE. Powerful automatic, manual, and true shape nesting speed tube and pipe cutting processes and maximize yield. This of course translates into money saved through waste reduction. The industry's most efficient nesting is achieved by calculating the best possible combinations based on actual geometry while common-line cutting cuts shared edges at the same time reducing time and pierce points."