Adjustable eccentric gear units for precise dosing with high delivery rates and high pressures

The adjustable eccentric gear unit permits linear and precise stroke length adjustment and thus highly precise dosing. The optimised motion sequence, even with partial stroke operation, results in a reduction of wear and noise compared to conventional lifting gears, especially with higher delivery rates and pressures.

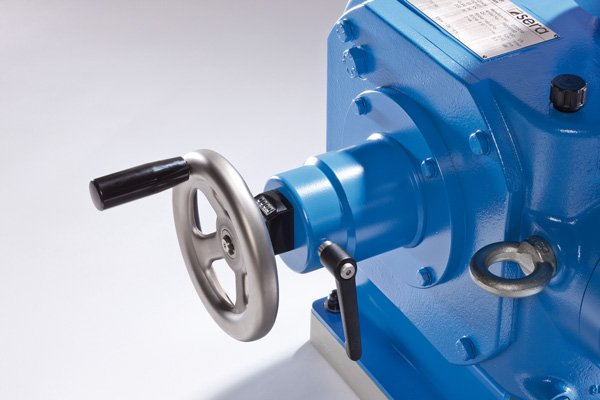

An adjustable eccentric drive differs from a conventional slider crank drive in that the cam can be adjusted radially. The length of stroke can be set precisely. The stroke can thereby be adjusted infinitely variably from 0-100 percent via a hand wheel with percentage indicator or a servomotor. The reproducibility of the setting is better than 1 percent.

Adaptable and suitable for a broad range of applications

The operating range of the new piston diaphragm pump of the 510.1 model series lies between 65 l/h and 1,300 l/h at a counterpressure up to 200 bar. The 511.1 model series reaches values between 100 l/h and 1,900 l/h at up to 220 bar. With this performance data, the new piston diaphragm pumps are suitable for a broad range of applications. The variable combination options further allow the pumps to be adapted to many other tasks in dosing technology.

Absolute operational safety

These pumps offer top safety in any application. The piston diaphragm pumps are equipped as standard with a high-quality material multi-layer diaphragm system that ensures positive diaphragm monitoring.

Furthermore, the pump itself is protected by an internal compensating valve. This valve primarily ensures the optimal amount of hydraulic fluid in the hydraulic chamber. A positive side effect of the valve is the limitation of the overpressure in the operating space of the pump. The valve thereby opens if the pressure is too high and allows the hydraulic fluid to flow into the reservoir. The compensating valve opens during the subsequent suction stroke and the missing volume of hydraulic fluid flows back again.

Because of the benefits outlined above the sera piston diaphragm pump is suitable for a very large range of applications. This encompasses dosing tasks in the food industry to applications in pharmaceuticals or petrochemicals.

Optionally also available with ATEX approval or API 675 conformity

To permit their use in crude oil pumping and processing, these pumps will optionally be available for explosion-protected areas as well as for the API Standard 675. The latter is especially made possible through the form-fitting connection of the individual components.

Comprehensive accessories complete the concept

Comprehensive dosing accessories, tailored to the requirements of the end user and the pump, are available. Altogether, the new sera piston diaphragm pumps of the 510.1 and 511.1 model series constitute a homogenous and consistent concept. Thus, sera continues to meet the customary high requirements for accuracy, quality and reliability.