H2 – a molecule with diverse application possibilities and equally diverse challenges

Today, the safe handling of hydrogen is technologically state of the art. In aerospace industry, crude oil refineries, in the production of semiconductors, as an inert gas during plasma welding, in the metal-finishing sector or as a source of energy in fuel cells, hydrogen can be found today in many commercial and industrial areas. As the list of possible applications grows, so does the demand for suitable sensors. However, manufacturers are faced with two particular challenges when products come into direct contact with hydrogen: Hydrogen embrittlement and permeation through hydrogen ions.

Hydrogen embrittlement corrodes metal, and its effect is equivalent to material fatigue. Cracks appear, and finally the material fails. In the case of permeation, hydrogen ions move through different materials. Therefore, not just the materials coming directly into contact with the media have to be considered, but also components located, for example, behind a sensor membrane, i.e. which do not come into direct contact with the medium to be measured. These problematic qualities of hydrogen limit the selection of possible materials so severely that many manufacturers of H2-compatible sensors are only able to provide them with a multitude of limitations, for example regarding the accuracy or the lifetime.

The solution

STW has a unique thin-film technology at its disposal, which permits the coating of material with the lowest hydrogen-related limitations during the manufacture of their own measurement cells and sensors: 316L. This alloy is outstandingly resistant to embrittlement through hydrogen, and is also the second-most frequently produced stainless steel, meaning that it is inexpensive to procure. By coating measuring cell blanks with TiON (titanium oxynitride), measurement cells with a high k-factor (gain factor) can be produced which permit the use of amplified circuits with a high signal-to-noise ratio.

In order to counteract the permeation of hydrogen ions, which is encouraged through higher temperatures and pressures, measurement cells can be designed with a high membrane thickness. However, a thicker membrane also means a reduction in the output signal of the pressure measurement cell. For such applications, STW has developed a further film package, which counteracts a reduced signal through an appropriate k-factor. This development from STW’s own cleanroom, provides an affordable solution for the manufacture of hydrogen application sensors even in high temperatures.

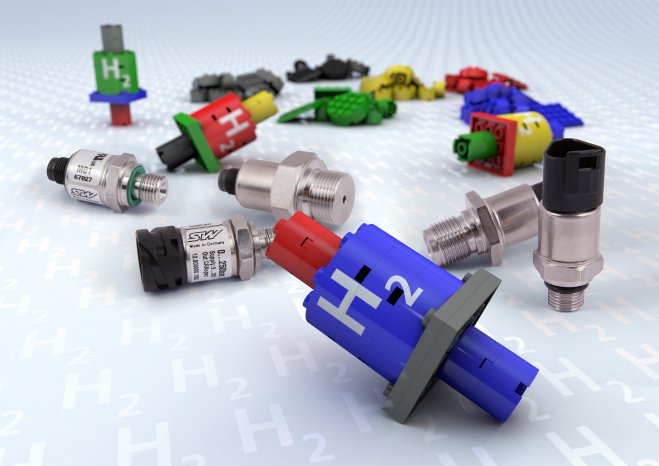

Hydrogen-compatible STW measuring technology portfolio

The measurement cells and sensors from the 316L group, which are suitable for use with hydrogen supplement the existing M01 pressure transmitter portfolio, which already comprises 1.5 million variations, so that the pressure and temperature of hydrogen can be measured. No expensive diaphragm seals were used. The stainless steel and the function layers of the Wheatstone measurement bridge of the thin-film measurement cells have proven their high level of reliability in complex endurance and load cycle tests with hydrogen. Customers of STW are now able to assemble a suitable transmitter for hydrogen within a pressure range from 3.5 to 900 bar. Amongst other things, 20 pressure connections, 10 electrical plugs and 9 electrical interfaces are available for selection. Qualifications acc. UL, CE, E1, ASIL, SIL, PL, calibrated, are possible (ATEX in preparation).

These products measure hydrogen and yet remain robust

The overpressure resistance remains at a very high level, even on the hydrogen-resistant variation. For example, the 3.5 bar variation can be overloaded by up to 20 bar without incurring damage. As both the measurement cell and the pressure channel consist of 316L stainless steel, the medium does not come into contact with any other material, and no seals affect the excellent media resistance. The burst pressure, accuracy, environmental properties, load cycle resistance and EMC characteristics mainly accord with the level of the M01 series.