Tailored optimally to the requirements of laminar-flow monitoring, the new flow sensors SS 20.415 and SS 20.515 from SCHMIDT Technology are working according to the thermal anemometer principle. They measure flows from 0.05 m/s (standard velocity wN of air, based on standard conditions 20°C and 1013.25 hPa). In addition to the very low beginning of the measuring range, extremely high measuring accuracies are required by the narrow acceptance tolerances for the measurement of the velocities of directed low-turbulence displacement flows. Due to the optional high-precision calibration, the measuring accuracies are within ±1% of the measured value. Compared to the standard calibration, the high-precision calibration features a further improvement in the accuracy by the increased number of adjustment points as well as the documentation of the nominal and actual values as ISO calibration certificate. This calibration can be renewed in cycles, for example annually, upon request of the user.

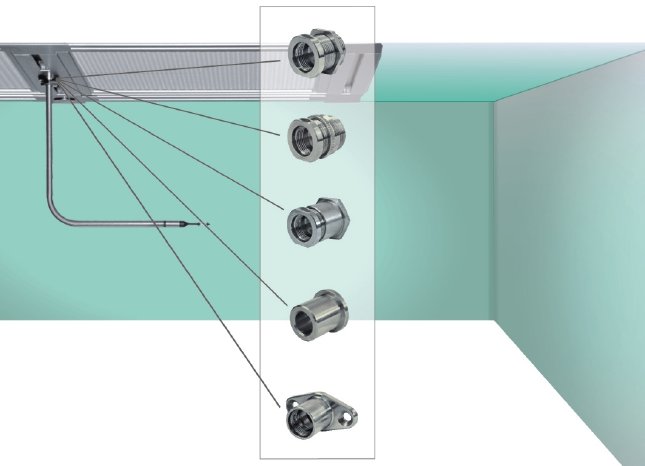

Also the design of the SCHMIDT® flow sensors is tailored to the special requirements of laminar-flow monitoring. This ranges from a cleanroom-suitable quick-mounting system which allows the easy mounting of the SS. 20.415 and SS 20.515 in ceiling or wall systems to the electronics which is completely integrated in the sensor tube. Thus, the electronics does not create any turbulences in the low-turbulence displacement flow and the sensors can be removed easily for calibration purposes as no separate evaluation unit has to be removed.

Concerning the measuring principles, the users can choose between the 'thermopile' and 'dumbbell head' sensors. The thermopile sensor of the SS 20.415 uses its heated semiconductor to detect the flowing cooling air. This measuring principle simultaneously offers the option of detecting the direction of flow on the basis of the difference in temperature of the two temperature sensors. Thermopile sensors are distinguished in particular by their mechanical sturdiness and extremely quick response time of 10 ms.

With the 'dumbbell head' measuring principle, the flow sensor in its stainless steel sleeve between the two 'dumbbell disks' is heated to 40 K above the temperature of the medium. This temperature is measured with a separate temperature sensor. The power required for maintaining the excess temperature is a measure of the flow velocity, which is output as 'standard velocity'. Thus, no additional measurement of pressure or of the temperature of the medium is required.

The aerodynamically optimized dumbbell head sensors are particularly easy to clean, even when switched on. The coated design also allows their use in aggressive media. Another thing worth mentioning is that both sensors, the SS 20.415 as well as the SS 20.515, are suitable for disinfection with alcohols such as isopropanol and with H2O2.

Depending on the requirement, the SCHMIDT® flow sensors with standard and high-precision calibration offer maximum accuracy which reaches a new quality level by the adjustment and calibration under application conditions in the unique vertical flow channel.