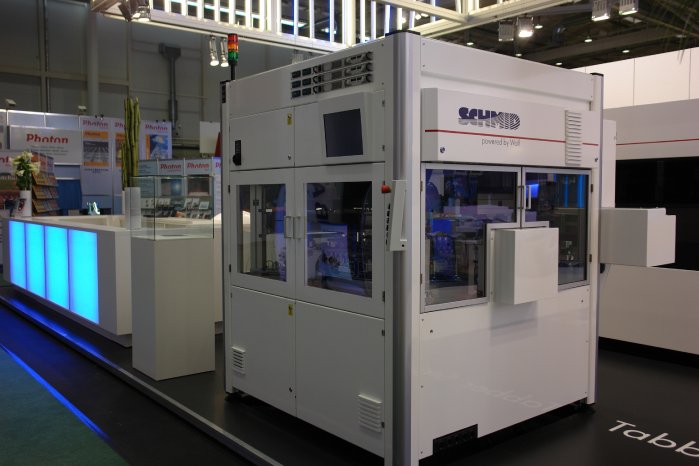

A special attraction at this year's show was the innovative Tabber Stringer, created in cooperation with the Wolf company, as its technology has been developed quite independently of the old concepts. This new, innovative system is very compelling due to a high precision performance combined with minimum handling and a soldering method that radically reduces the risk of cell damage.

The new Tabber Stringer also cuts a fine figure with its space-saving foot-print of only 3.3 m² while its price, at 590,000 €, is without competition.

Tabbing and stringing is carried out in two steps whereby minutely exact positioning of the solder ribbons on the rotating table of the tabbing unit and highest repetition precision are guaranteed. The accuracy of cell positioning along the linear axis in the stringer unit allows production of one-hundred percent straight and regular strings for the first time ever.

The use of different stations for quality control prior to and during the process and the automatic rejection of defect cells ensure a constant level of high quality while preventing the production of faulty strings.

The combination of soldering processes is a new feature of this application. Contact-free resistance heating is used to bond the ribbons to the cells. The uniform temperature profile generated along the entire solder ribbon-busbar connection during this process creates a homogenous, high quality solder result. The tabbed cells are then connected in series to create strings, again by means of non-contact laser beam soldering. Both these soldering methods are lead-free and are characterised by highest-level accuracy, repeatability and lowest possible maintenance requirements.

The new Tabber Stringer impressively combines strong output performance (1,200 cells per hour) with a minimum breakage rate (< 0.3 %) and space-saving design. An upgrade from 25 MW to 50 MW can be accomplished at low cost and little effort and does not require additional space.

The possibility of processing very thin cells from 130 µm also makes the system an extremely interesting solution in view of current developments in solar cell production.

Schmid will deliver the first Tabber Stringer to customers as early as January 2010.