Increase in performance thanks to Mancrodur

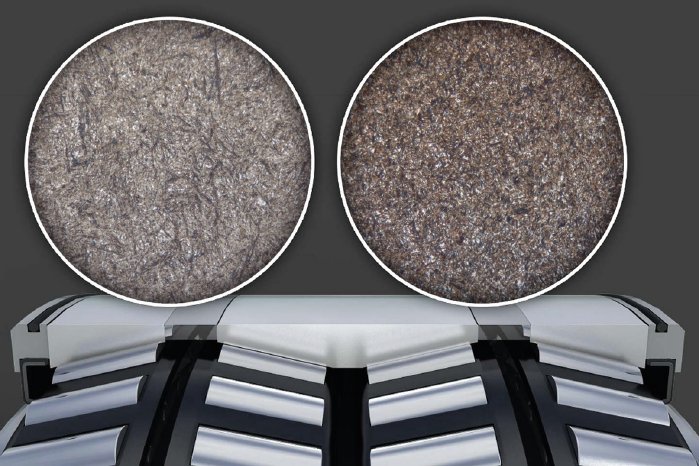

Spherical carbonitrides are formed when high-performance steel Mancrodur is enriched with nitrogen during the carbonitriding heat treatment process. A fine and even structure is produced. This increases the tapered roller bearings' surface hardness and wear resistance.

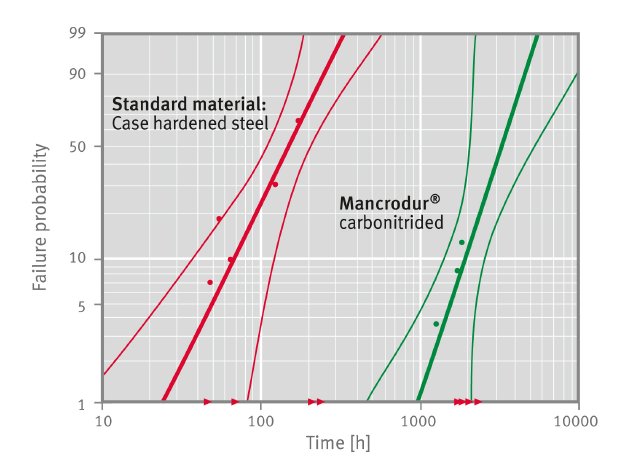

The wear resistance and improved structure ensures a significantly longer operating life during particle overrolling and mixed friction (boundary lubrication conditions). This leads to considerably higher machine efficiency in the application.

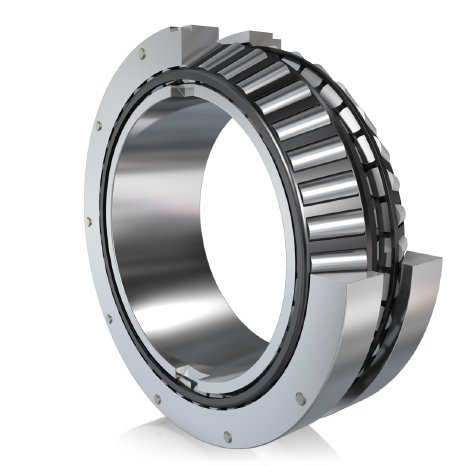

Specialist in large bearings

When it comes to large-size bearings, Schaeffler is recognized as an absolute specialist. Standard and special bearings from the INA and FAG brands with outside diameters of 320 mm and above have been leading the way in applications in heavy industry such as the metal and non-ferrous metal industries for several years now. Large-size bearings are machine components, and their quality and reliability is of decisive importance for the function and cost-effectiveness of the application. Schaeffler's wide range of designs and variants combined with our many years of experience ensure comprehensive expertise in large-size bearings that fulfills the special requirements of these applications.