- Higher speeds and higher torque

- New rotor design

- Particularly suitable for turning and milling centers

- Very high performance, cost-effectiveness and energy efficiency

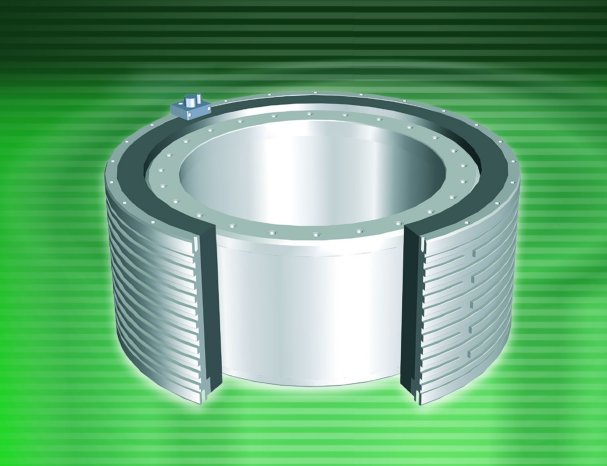

INA Drives & Mechatronics GmbH & Co. oHG (IDAM) – the specialist for direct drive technology within the Schaeffler Group– is extending its range of motors and opening up new fields of application with the high-performance rotary direct drive series RKI. This innovative drive design results in excellent motor constant values. The drives achieve high torques and speeds with low heat generation and thus offer very high performance, cost-effectiveness and energy efficiency.

The internal design of the standard RI series drive with internal rotor was completely revised for the newly developed motor series. While the rotor in the RI drive was a homogenous steel part, the rotor in the RKI is a subassembly, whose core is formed by a laminated magnet holder. This means that eddy current losses are reduced to a minimum. Heating of the rotor is reduced and is no longer the limiting factor for motor performance. This allows significantly higher speeds. In addition, the permanent magnets in the rotor are arranged so as to maximize the magnetic flux. Higher torques are achieved due to the innovative design and the resultant concentration of the magnetic field.

Optimization of the motor data map in the high-performance rotary direct drive motors RKI is of particular benefit in production machine building applications. The use of the RKI series has special advantages in turning and milling centers. The operating range of these machines can be extended significantly due to the increased speed and torque ranges. The excellent static and dynamic load rigidity as well as the very good uniform running characteristics of the motors come into their own in these applications, resulting in high precision machining and high surface quality.

The motors of the RKI series are available in different diameters and are based on the dimensions of the proven IDAM RI series.