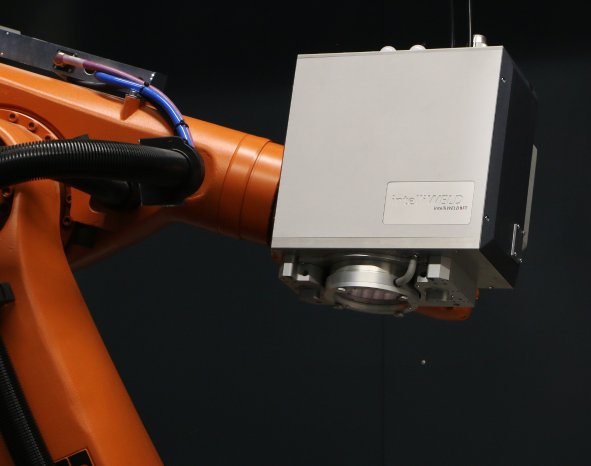

Remote welding - with scan heads mounted on industrial robots - is widespread in auto manufacturing, and offers considerable potential for other branches, too. Here, the scan system manages laser fine-positioning, thus eliminating time-robbing robot repositioning. This has significantly boosted beam utilization rates and manufacturing productivity over the past few years.

At the tradeshow in Munich, SCANLAB will exhibit a fully functional prototype of the intelliWELD II FT, which delivers more freedom and flexibility to users. The completely new additional zoom axis allows highly dynamic, step-less varying of spot size up to x 1.5 - accompanied by uniform intensity distribution ('top-hat' profile). This enables flexible width adjustment within a seam or for diverse seams on one or multiple workpieces.

High-Performance Solution Platform for Remote Laser Welding

Over recent years, the combined system solution of intelliWELD scan heads and Blackbird's ScanControlUnit for industrial control has proven its value in 24/7 industrial deployment. The unique solution of a scan head with pre-focus optic is optimized for vision-assisted applications such as fillet welding, with precise seam tracking to an accuracy of 0.1 mm. The new scan system with integrated zoom axis logically extends SCANLAB's product range by adding an application-specific solution package for overlap welding.

The scan head's mechanics, too, fulfill all requirements for industrial manufacturing: a sealed housing with encapsulated optical path and a replaceable protective window with newly-developed protective window monitoring. The system is equipped with latest-generation galvanometer scanners that offer advantages such as minimal position drift. The optical components accommodate disc and fiber lasers with up to 8-kW power. Additionally, integrated internal flash memory stores the scan head's configuration data and correction files. The intelliWELD II FT scan head will become available for ordering in Q4 2015.

Starting January 2016, Blackbird's field-proven ScanControlUnit will be available in a new modular 19-inch rack version. This enables exceptionally straightforward expandability, and rapid onsite module-swapping if service is required. The control panel will be separate from the control unit itself and even installable far away from robot cells, fully in accordance with customer needs.