The demands of the plastics processing industry are constantly rising, films are becoming more thin-walled, fibers increasingly finer. The requirements for the dispersion of the pigments and fillers used are also growing at the same rate. The market for well-dispersible pigments is extensive, however there is often a need to use pigments that are not easily dispersible. Consequently, methods for determining the dispersion quality are gaining in importance. Common methods used in practice range from visual assessment of injection molded platelets or film samples under a light or scanning electron microscope through to the filter pressure test (FPT).

ROWA Masterbatch started an intensive, six-month test phase with the procurement of a new test device from Collin Lab & Pilot Solutions in the autumn of 2022, which was primarily planned and implemented by master student under the supervision of Dr. Susann Neubert, Head of Quality Assurance: This centered on an E25E-MP-IS filter test with melt pump and integrated screen changer. This test system standardizes the sequence of the entire test process and enables the filter to be changed without interrupting operation, thereby reducing the pure measuring and evaluation time, depending on the test specification. A laboratory extruder with a 25 mm screw diameter (25 D) was used to prepare the melt. All common technical plastics up to 300°C can be tested using the system. The test was performed with reference to DIN EN ISO 23900-5. The filter pressure test provides an objective measurement parameter that can be used to determine the quality of the dispersion of pigments and fillers in masterbatches.

Method and implementation:

In the first step, the natural material is extruded, then the masterbatch is added. The test material is melted in a single-screw extruder, homogenized and conveyed through a screen via a melt pump with a defined and constant volume flow. Particles above a specific size can clog the screen and consequently reduce the free flow through area of the screen. As a result, a greater pressure builds up in front of the screen, which is detected by a sensor. The pressure increase can be used to draw conclusions regarding the dispersion of the pigments and impurities or fillers. The measured pressure increase is related to the amount of pigment used. Conclusions on dispersion can be derived from the determined filter pressure value (FPV). The following applies: the smaller the filter pressure value, the more effectively the pigment is dispersed and the higher the product quality. A built-in melt valve enables the test screen to be changed while the melt preparation continues to run uninterrupted - it is not necessary to shut down or stop the measuring device. The master thesis investigated the influence of process parameters, such as different screw speed, throughput and split-feed process, in different polymers (LD-PE, PA6 and PMMA) with different, difficult-to-disperse pigments (Pigment Green 7, Pigment Black 7 and Pigment Red 122) and the use of different dispersing additives.

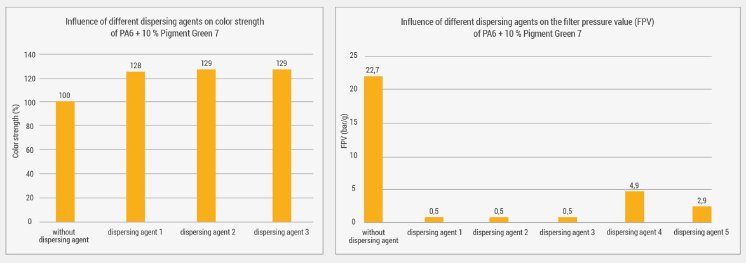

The project team initiated a total of 115 individual tests on a ZSK26 technical center. In addition to the filter pressure value, the dispersion quality was also assessed on 50 µm thick flat films by means of a camera system and the color strength on white lightened injection molding platelets (s. diagram: Influence of different dispersing agents on the color strength).

Results and conclusion:

It was possible to demonstrate that the dispersion of, for example, Pigment Green 7 in PA6 was significantly improved using all the dispersing additives tested, while the process parameters remained unchanged. In contrast to the manufacturer's specifications, it was observed that not all dispersing additives were equally effective. The filter pressure value (FPV) was determined with a 10 µm screen. It was also confirmed that the improvement in dispersion of the pigments used simultaneously led to increased color strength. To achieve this, the masterbatch was lightened with a white pigment, as the color would otherwise be too saturated and it would not be possible to detect color differences.

An improvement in dispersion quality of up to 99.6 % was achieved in the production of 50 µm flat films (2 % masterbatch in PA6). As a comparison, flat films of the carrier polymers were previously prepared to quantify the defects caused by bubbles and gel bodies. Predictably, the addition of dispersants resulted in a significant reduction in agglomerates, which was consistent with the reduction in pressure filter values (s. diagram: Influence of different dispersing agents on FPV). The flat films produced were examined using an optical microscope (s. diagram: left without dispersant additive, right with dispersant additive). The image demonstrates that the flat films produced with dispersing additives exhibited a lower number and smaller sizes of agglomerates, indicating better dispersion of the pigments.

The project team, which included Dr. Neubert and M.Sc. student Mani Zendedel Haghighi, as well as Dorit Krienke, Head of Color Masterbatch Development, and Dr. Natalia Olichwer, Head of Additive Masterbatch Development, concluded that the determination of the filter pressure value is the visual testing of pigment dispersion on thin flat films. The Collin filter test is now an integral part of process development/optimization at ROWA Masterbatch and makes a relevant contribution in terms of quality standards.