A metallic surface is a sought-after property for various plastic parts, not only as a decorative feature, but also regarding their functional use. Today, these surfaces are still largely produced using galvanic processes.

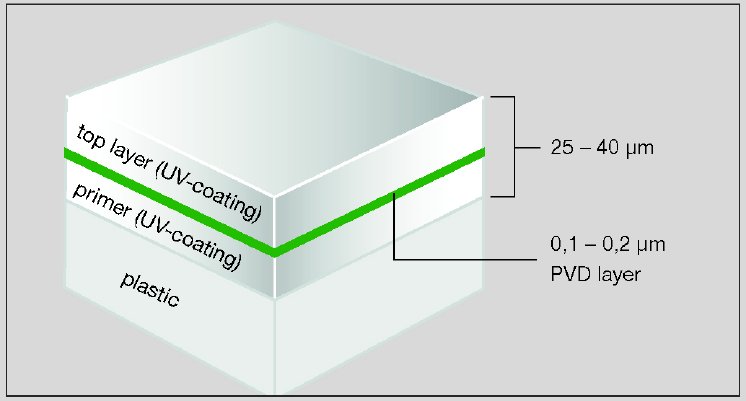

Due to environmental problems, especially when chromium (VI) compounds are used, metal deposition from the gas phase, known as the physical vapor deposition (PVD) process, is gaining in importance.

The process as a whole is also emission-free if using UV-curable coatings as a top layer. With the use of different chemical elements or compounds, certain special effects and properties can be obtained that cannot be achieved by using the electroplating process.

The prerequisite for successful PVD processing is to use a base material with a special property profile, especially with regard to surface quality and optical properties. ROMIRA has succeeded in developing PC-based blends that fully meet these requirements. The PVD process can also be shortened by one process step when using ROMIRA products.

About the ROMIRA GmbH:

The ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, ROMIRA sets standards for technical plastics with its profound competence and synergetic know-how.