Surface design

Rotec acrylic compounds fascinate with their brilliant depths of color and have been used for unpainted exterior parts in jet-black, attractive design colors and high-gloss finishes in the series production of leading automobile manufacturers for many years. There is currently a big demand for materials with a deep color impression in not just black to design vehicles of future. Whether in red, green, blue or white, the surface of parts made from Rotec acrylic compounds is impressively brilliant. Metal effects in particular can be very easily mapped.

Thanks to the color competence of the ROWA GROUP as expressed in the Color Competence Center, individual color adjustments can be carried out in consideration of the requirements on color stability due to UV radiation and/or weathering. The unique Rotec acrylic compounds from ROMIRA with the type designation Rotec AC-MA 500xx and the newly developed Rotec AC-MA 700xx series with a higher heat deflection temperature also have a high impact strength and very good scratch resistance compared to other uncoated plastics. The acrylic compounds allow scratches to be removed by polishing, unlike other thermoplastics that are used outdoors, thus restoring a smooth and shiny surface – one advantage that thermoplastics containing PC or ASA, for example, are unable to offer. Compared to similar products on a PMMA basis from other manufacturers, these products offer an up to 30% better process stability and an extended process window in the opinion of professional processors. This means that the component no longer requires painting. It is almost impossible to tell the difference between a painted car component and an assembly part made from an unpainted Rotec AC-MA compound.

Functional properties – anti-squeak and with slip agent

The use of tribologically functionalized compounds is a low-cost and permanent solution compared to complicated work with anti-squeak paints or the manual application of anti-squeak tapes at the points of contact or the use of lubricants. ROMIRA has been working successfully on the development of tribological compounds in automobile manufacture for many years and can offer solutions wherever direct contact between components is unavoidable for design and engineering reasons. Specially developed copolymers with the trade name Modiper from the firm of NOF in Japan, distributed by Marubeni in Europe, are used in this case. Modiper generally improves the anti-squeak characteristics, even when added directly to the corresponding plastic during the injection molding process. However, in most cases it lacks the good dispersions and the compatibility that can affect the long-term properties of the parts manufactured from this material. Special attention has to be paid to the recipe formulation depending on the plastic matrix: thus, the innovative Romiloy and Rotec compounds, for example on the basis of ABS, PC+ABS, PC+ASA, PA and PBT, have been developed to achieve the tribological effects specifically for applications of plastic parts even after long-term tempering at high temperatures against PA compounds with mineral or glass reinforcement, and also with synthetic leather as a friction partner.

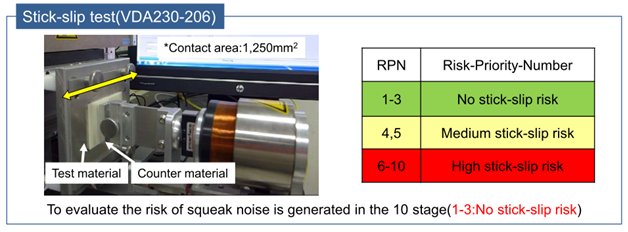

Squeaking and creaking noises are determined on the basis of the so-called stick-slip test pursuant to VDA 230-206. The creaking noises between the friction partners are recorded after defined forces and frictional velocities have been applied and the result is determined as a Risk-Priority-Number (RPN) from 1 to 10 (see Figure 1).

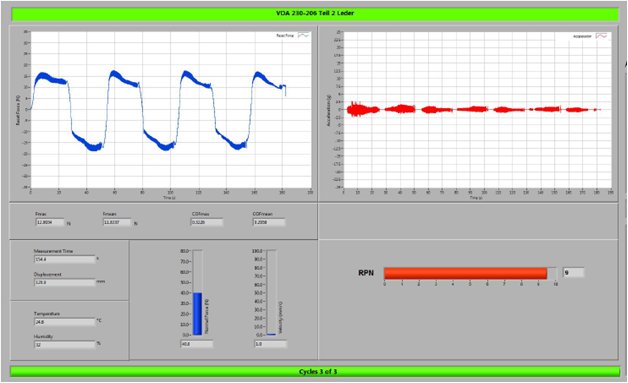

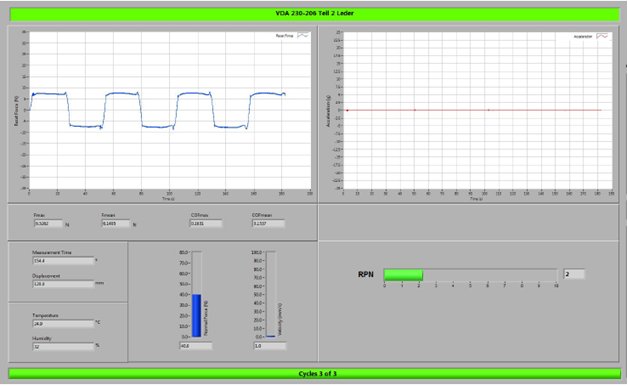

Figures 2 and 3 show the results of friction pairings between leather and Rotec ABS with an anti-creak finish compared to a standard ABS. The reduced frictional resistance with an RPN of 2 for the anti-creak-modified Rotec ABS can be seen very clearly (Fig. 3) compared to an RPN of 9 with the standard ABS (Fig. 2)

Solutions to problems with tribological compounds from ROMIRA GmbH that can be named here from the series of successful applications include folding brackets, armrests, door locks, slide rails, ashtrays as well as sliding roof elements. These compounds also have benefits over material solutions with PTFE-additives, which have a lower surface quality and are subject to higher wear in endurance tests. Parts made of ROMIRA compounds, on the other hand, are characterized by a very good abrasion resistance and long-term properties and require no additional painting.