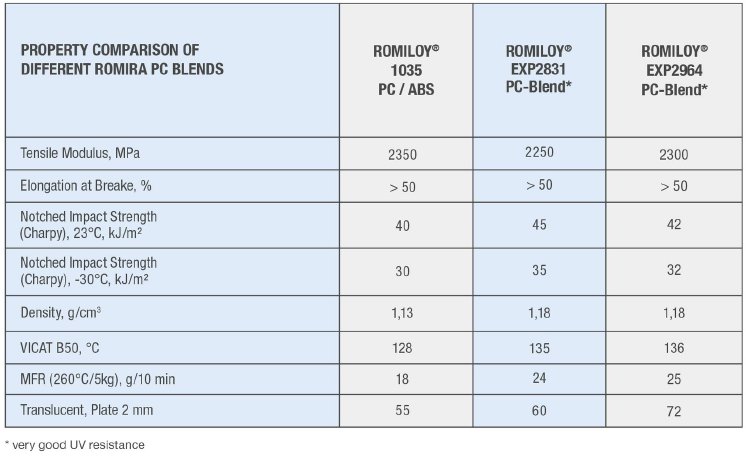

Pure, unmodified polycarbonate is one of the transparent materials, but is unsuitable for many applications due to its poor inherent impact strength at low temperatures. This brittleness can be reduced by suitable additives, but always at the expense of transparency or translucency.

The ROMIRA experts have now succeeded in impact-modifying polycarbonate with a new formulation and process development, while maintaining a high level of translucency. At the same time, the higher level of translucency allows for brilliant and deep color adjustment of the products.

The photo covers the difference in quality very clearly: sample plates produced with standard material on the left and right side of the picture. In the middle it presents a sample of the newly developed ROMILOY® showing clean, translucent lettering in red and black.

With a new stabilization package, ROMIRA also knows how to counteract the inherent yellowing tendency of polycarbonate. Another advantage, in addition to the good UV resistance, is the lower use of colorants.