- Renesas Electronics 7th-Generation 650 V and 1250 V IGBT Series sets a new technology benchmark enabling high efficiency solutions in Industrial Applications such as Inverters for Solar Power and Industrial Motors

- 7th-Generation IGBTs Offer Low Saturation Voltages of 1.6 V for the 650 V Series, and 1.8 V for the 1250 V series to minimize power losses

Renesas Electronics, a premier supplier of advanced semiconductor solutions, today announced 13 new products in its 7th-generation Insulated Gate Bipolar Transistor (IGBT) lineup with industry-leading high performance. The new IGBTs include the RJH/RJP65S series for 650 V and RJP1CS series for 1250 V. The new IGBTs are power semiconductor devices used in systems that convert DC into AC power, and are designed for applications that handle high voltages and large currents, such as power conditioners (power converters) for solar power generators and industrial motors. The 7th-generation technology, based on enhanced thin wafer process, sets a low losses trade-off between conduction, switching losses and robustness capability to withstand short circuit conditions.

Compared to the previous 6th-generation technology, products series of 600 V and 1200 V, the 7th-generation portfolio has higher voltage rating 650 V and 1250 V to address low temperature performance requirements and overvoltage blocking capability.

Renesas IGBTs are suitable in motor controls applications. In such cases the device short circuit capability is a design critical selection parameter. The 7th-generation IGBT series comes with a 10 µs rated short circuit tolerance making it suitable for motors in general.

Recently, concerns for environmental preservation and other factors have prompted the need to improve the energy efficiency of electrical equipment as well as an ongoing shift toward clean energy such as solar and wind power. Such efforts to boost energy efficiency have been vigorous in the area of equipment that handles high voltages and large currents, such as solar inverters, water-jet pumps, and large-current inverter-controlled motors. This has spurred demand for dramatically reduced loss in IGBT products used in the conversion of power from DC to AC for this type of equipment. However, there is a trade-off between saturation voltage (Note 1), which is key to reducing loss, and the high short circuit tolerance required in the equipment that handles large currents. It has been difficult to achieve low loss along with a high short circuit tolerance (Note 2) of around 10 microseconds, which is considered essential in applications such as motor drives. In response, Renesas has developed these high performance IGBTs.

Key Features of the new IGBTs:

1) Reduced saturation voltage of 1.6 V for 650 V versions and 1.8 V for 1250 V versions for better power efficiency

The exclusive ultrathin wafer technology reduced the saturation voltage to 1.6 V (typical value) from the 1.8 V (typical value) of comparable earlier Renesas products for the 650 V versions and to 1.8 V from 2.1 V for the 1250 V versions, a drop of about 12 percent and 15 percent in each case. This reduces power loss and contributes to increased efficiency.

2) High short circuit tolerance of 10 microseconds for a higher level of reliability

The high short circuit tolerance, essential in applications that handle large currents, has been improved from the 8 microseconds (μs) range of comparable earlier Renesas products to 10 μs or above by optimized cell structure technology. This ensures excellent reliability and robust performance in systems such as power conditioners for solar power inverters.

3) Faster switching

The reverse transfer capacitance (Cres) (Note 3) has been lowered by approximately 10 percent compared with earlier Renesas products by optimizing the surface structure of the device. This contributes to faster switching and makes it possible to build more efficient power converter circuits.

These improvements contribute to lower power loss and more stable operation in applications such as the three-phase inverter circuits widely used in large-current inverter blocks of solar power inverters or inverter-controlled motors for industrial use.

Renesas benefits customers by offering total solutions combining microcontrollers (MCUs) with analog and power devices. The new high-performance 7th-generation IGBT products take their place among the best power devices in the world in their category. They form the core of the Renesas lineup of power devices, and the company plans to release new products in the series moving forward.

Renesas also plans to release an enhanced line of kit solutions consisting of the new IGBT products with Renesas' RL78 and RX families of MCUs for motor and inverter control and photocouplers for power device drive, among other combinations. Renesas is also preparing reference boards mounted with the new IGBT products to support customers' kit evaluation and system design.

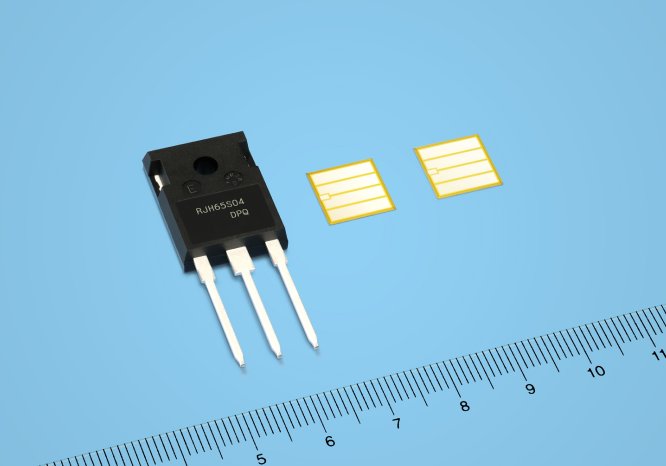

Shipping formats for the new IGBT products are wafer/chip and TO-247A package for the RJH65S series.

Note 1: Saturation voltage (VCE(sat))

This is the most important index of the performance of an IGBT. It indicates the collector-emitter voltage drop when the device is conducting current. The lower the value, the smaller the conduction loss.

Note 2: Load Short Circuit Tolerance (tsc)

An index of an IGBT's ability to withstand destruction. It indicates the amount of time before the IGBT is destroyed by unlimited current flow due to a short circuit. Generally speaking, a high value is desirable for applications demanding large current handling and high reliability, such as motor drives.

Note 3: Reverse transfer capacitance (Cres)

A parameter indicating the intrinsic capacitance between the gate and collector of the IGBT. Generally speaking, a smaller value mean faster switching of the device is possible, resulting in reduced switching losses.

Refer to the separate sheet for the main specifications of the IGBT series.

Availability

Samples shipments of Renesas' 13 new IGBT products, including the RJH/RJP65S series for 650 V and the RJP1CS series for 1250 V, are scheduled to begin in July 2012. Mass production is scheduled to begin in September 2012 and is expected to reach a scale of 500,000 units per month by April 2013. (Availability is subject to change without notice.)

Remarks

All other registered trademarks or trademarks are the property of their respective owners.