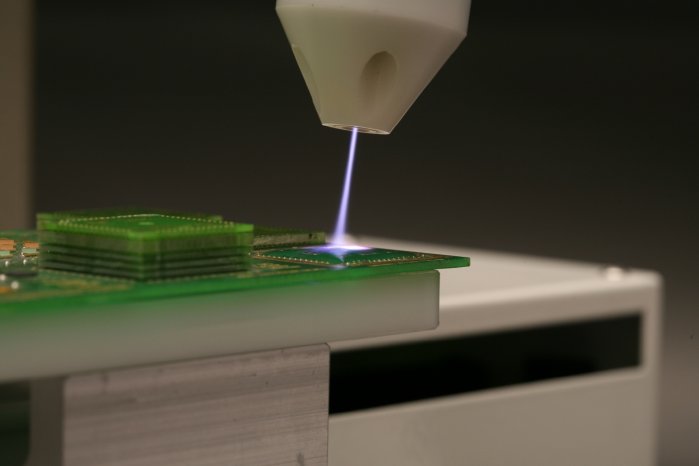

Plasma treatment is often used to prepare components for subsequent processing by modifying the bonding strength of their surfaces - preferably under atmospheric pressure, because this process means there is no need for any reactor, pump or lock systems which in turn makes integration into automated processes simpler resulting in shorter cycle times. With its patented Plasmabrush technology, Reinhausen Plasma GmbH offers a coldactive plasma tool that combines the benefits of lowpressure plasma processes such as high plasma activity and low thermal material stress with the simple automation of atmospheric plasmas. In addition the specific physical properties of the coldactive plasma generators Plasmabrush PB1 and PB2 ensure enhanced process reliability and efficiency for the surface treatment of metals, plastics (z.B. PMMA, POM, PP, PE, PA 6, PA 12, elastomers and silicons), glass ceramics and papers. This technology also enables the cleaning and activation/modification of materials that cannot be treated with conventional, socalled "cold" atmospheric plasmas.

Plasmabrush PB 1 - colder, slower, more gap accessible and purer

Lower temperatures, slower gas speeds, higher ability to access even the smallest gaps and its gas purity are the outstanding features of the patented Plasmabrush system when compared to conventional plasma generators for surface treatment that work on the principle of ambient pressure.

The difference in temperature results from the generation of the gas plasma. This is effected with PB1 by means of dielectric barrier discharge (DBD), which causes acceleration of only the light electrons. The result is a cold, nonthermal plasma that has a maximum temperature of 70 °C under ambient pressure. The low temperature means that even very thin and/or temperaturesensitive substrates such as plastics, films, paperboards and paper can be treated harmlessly.

At the same time the PB1 can be operated with low gas flow volumes resulting in a laminar gas flow that prevents nonactivated ambient gas being whirled in. The backpressure in front of a surface against which gas flows is so low that even very small and light components can be treated. Thanks to the laminar flow properties the plasma spreads over the surface uniformly and reaches into the smallest cavities, undercuts and smallest gaps. The PB1 can be moved statically over structured, threedimensional and complex substrate geometries in a processing path width of 30 mm per nozzle, so that uniform treatment of the whole surface can be achieved. Up to three plasma heads can be arranged in parallel or offset to each other for the treatment of wide components.

The high stream density and the high gas temperature in conventional atmospheric pressure plasma generators can lead to local fusings on the excitation electrodes. More often than not the metal removed by the plasma is deposited as an impurity on the surface of the substrate being treated and impairs the quality of the pretreatment. This is prevented in the Plasmabrush thanks to its low temperature and special patented design, making the system suitable even for cleanroom applications.

Plasmabrush PB2 - highperformance for industrial applications

A speed of 600 meters/minute and a path width of 40 mm per nozzle means that the PB2 meets the high demands of efficiency and costsaving for the pretreatment of large surfaces such as the cleaning of metal tapes before coating, stripping of paint from wires before bonding and activation of elastomers before painting. The company in Regensburg did prioneering work in the generation of plasma gases to achieve this. Generation is carried out on the inverter principle by means of highly effective, pulsed arc discharges. Whereby, a cold nonthermal plasma is generated whose maximum temperature of 120 °C is still considerably lower than that of conventional "cold" atmosphericpressure plasmas. The turbulent flow of the plasma can access gaps and contours of down to 10 mm.

Both systems are available as standalone devices as well as versions for simple and spacesaving integration in line and robot processes. The central control of the PB2 is designed for the operation and control any desired number of plasma generators. www.reinhausen-plasma.com