Thermoplastics, thermosetting plastics, elastomers, CFRP - numerous parts and components made of plastic need surface cleaning, activation or modification of the surface before further processing, such as adhesion, coating, varnishing or lathering. Reinhausen Plasma GmbH offers plasmabrush systems PB 1 and PB 2 for this purpose, with innovative, cold.active plasma tools that combine the advantages of lowpressure plasma procedures, such as high plasma activity and low thermal material stress, with the simple automation of atmospheric pressure plasmas. In addition, the specific physical characteristics of the patented plasmabrush procedure ensure a high level of process reliability and efficiency in the surface treatment of plastics (such as PMMA, POM, PP, PE, PA 6, PA 12, elastomers and silicones). The systems with multigas capability can also be used to clean and activate/modify plastics that cannot be treated with conventional, "cold" atmospheric pressure plasmas.

Plasmabrush PB 1 - treating very temperaturesensitive substrates reliably

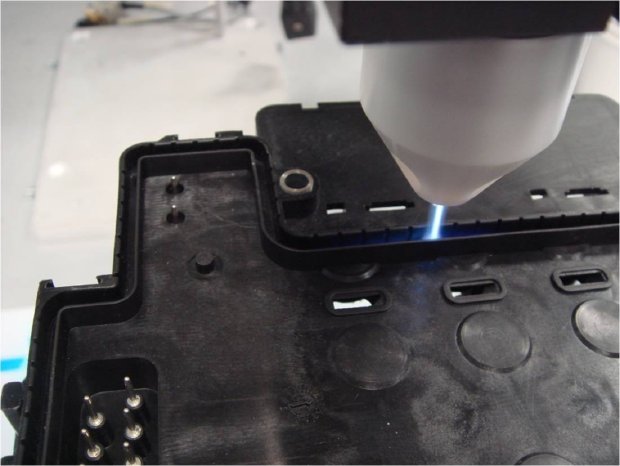

In contrast to conventional plasma generators for surface refinement that function under ambient pressure, the plasmabrush system PB 1 is distinguished by a low temperature, low gas velocity, the plasma's extremely precise ability to enter cavities and a high level of gas purity. The average temperature of the nonthermal plasma is thus 70°C on average under ambient pressure, which enables the materialfriendly, reliable treatment of very thin and/or temperaturesensitive plastics and plastic film. At the same time, PB 1 runs with low quantities of gas flow, which produces a laminar flow duct. The dynamic pressure in front of an illuminated surface is so low that even very light and very small parts can be treated. Due to the laminar flow properties, the plasma spreads evenly over the surface and can penetrate into the smallest cavities, undercuts and finest gaps. The plasmabrush is also suitable for applications in a clean room.

Plasmabrush PB 2 - highspeed for highest productivity

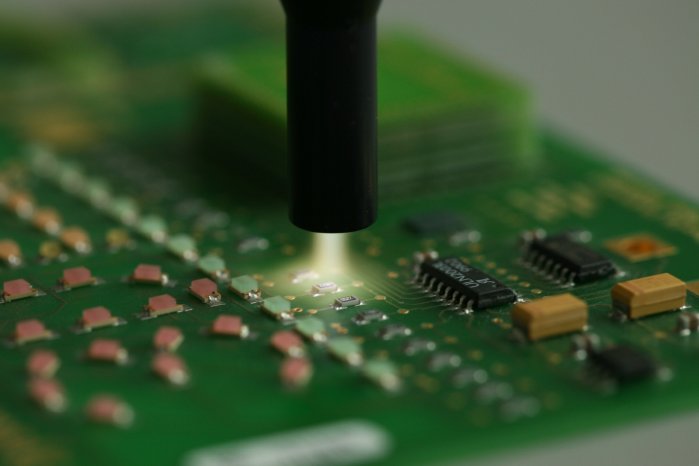

With a speed of up to 600 meters/minute and a width of up to 40 mm per nozzle, the PB 2 is designed for maximum productivity and efficiency in the pretreatment of plastic surfaces. With this system, the gas plasma is produced according to the inverter principle via a highly effective, pulsed arc discharge. This creates a cold, nonthermal plasma with a temperature, depending on the nozzle, of between 120°C and 250°C at ambient conditions, which likewise lies below the conventional "cold" atmospheric pressure plasmas. The turbulent flow of the plasma exhibits a precise ability to enter cavities of up to 10 mm. Fields of application may be the cleaning and activation of plastic addon components such as bumpers, mirror casings and emblems before varnishing or coating as well as the treatment of plastics before adhesion with metallic materials. In order to treat electronic and optoelectronic components safely and without damage, the company offers special plasma nozzles that transfer the plasma to the surface in a reliable and potentialfree manner.

Plasmadust - cleaning, activating and coating/metalizing in one process

Reinhausen Plasma has developed the nanopowder plasma deposition technology, known as plasmadust, based on PB 2. Using this innovative method, direct coating processes with metal, polymer, semiconductor and other coats can be carried out for the first time ever completely without solvents, in other words, VOCfree, on two and threedimensional plastic substrates. Etching and staining processes, which are indispensable in the traditional surface treatment processes, are not required either.

For the coating/metalization process, powder particles with a grain diameter of between 100 nm and 20 µm are continuously fed on an agglomerationfree basis to the plasma using a specially developed atomizer/handling technology. An adjustable, homogeneous particle flow ensures uniform and reproducible thicknesses. Practically all materials that can be reduced to powder form and that are meltable can be processed as coating materials, such as gold, copper, aluminum, tin, bismuth, tellurite, CIGS, polymers, thermoplastics, glass and ceramic materials. In addition, alloys and material combinations such as carbon/metal, which cannot be processed with conventional coating procedures, can be separated. The process thus not only offers a very broad range of applications, but also opens up new fields of application for plastics.

plasmabrush® and plasmadust® are registered trademarks of Reinhausen Plasma GmbH and will be presented at K 2010 in Hall 11, Booth F47.