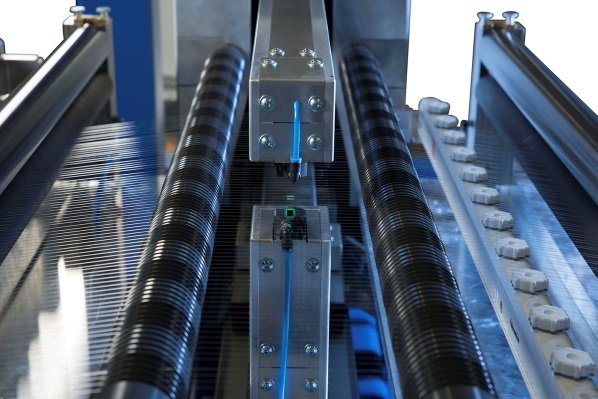

- The new sensor system measures monofilament diameters, thick and thin spots (called “slubs”) and is also used to create measurement reports for quality assurance

- The SDS/IDC system (Slub Detection System / Inline Diameter Control) installed in lines around the world is in high demand also in the paper industry for the production of filaments. Reimotec measuring systems are key components in these lines as well.

- Beside trend diagrams with information on tolerances, labels can be printed for the individual spools, and in addition quality certificates can be stored, showing for example the standard deviation of the filament diameter referred to the run length.

- The proven measuring system was completely redesigned and updated already in 2015. New sensors were developed for the diameter control system which give an absolute value of each filament in contrast to the comparison measurement used before.

- Totally modernized control system including an up-to-date computer system and specific evaluation software

- Upgrade of real-time computer for the SDS to ensure a longer spare parts availability

- With regard to strapping tapes, the 3rd generation of thickness and width controls will now be launched for inline quality control. Here the TCS Tape Control System can identify changes (for example viscosity variations of the raw material) in the extrusion process and their effects on the end product at an early stage to enable process parameters to be adapted accordingly.

- Reimotec will be exhibiting at K 2016 the ultimate design of both systems and explain customers the benefits of this technology in more detail.

- The new laboratory line equipped with newest engineering technology will be available at the company's location in Lampertheim for demonstrations as well as product development and further improvement. The extrusion line is able to produce monofilaments, strapping tapes and artificial grass filaments on a laboratory scale.

- The prototype of a fully automatic strapping tape winder developed in 2015 can be tested in the Reimotec Technology Centre as well as a fully automatic monofilament winder installed in the pilot line.

Story Box-ID: 805086

Website Promotion