De Grood had previously worked for a Dutch research institute and developed printer heads for industrial applications. With his knowledge of printing, he saw possibilities in designing a printer for food manufacturers and began working on a prototype that could digitally print custom-designed, edible high-viscosity decorations onto mass-produced food products. This food printer would also need to quickly switch from one decoration/design to another and from one food product to another with minimal production down-time.

Initially, the design work was done in de Grood's spare time, spending a year testing and trying to develop the printer head. Once he designed a printer prototype that worked well, he spent the next two years optimizing the system. During that time, De Grood received patents for the technology in Europe and North America.

The printer’s development work was entirely funded by De Grood Metaaltechniek. Pascal de Grood explains, “We invested 3 years and a lot of money in this technology, which was not an easy feat for a small business. But we managed and our first machines generated a lot of interest from potential customers.”

Because of its low maintenance requirement, ease of cleaning and low price per droplet, the De Grood Innovations BV FoodJet printer is ideally suited for the food industry. Main target markets are bakeries, and manufacturers of ice cream and dairy products.

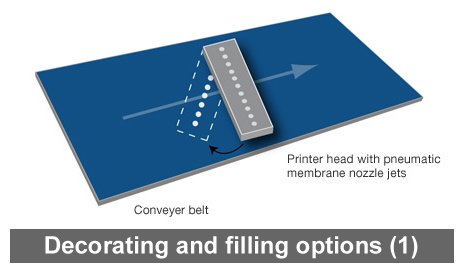

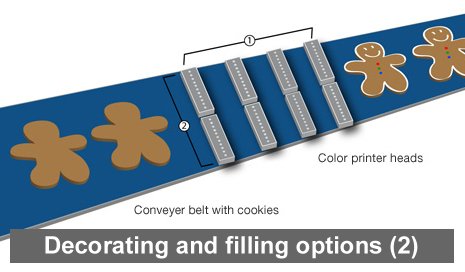

The FoodJet printer is designed to accurately deposit a variety of thick food materials such as frosting, yogurt or sauce onto food substrates. The system’s series of pneumatic membrane nozzle jets deposit small drops onto the moving food products. These drops then form a digital image in the shape of a decoration or a surface fill. Decorating requires higher resolution and smaller nozzle (droplet) size while filling can be done using big drops and lower resolution.

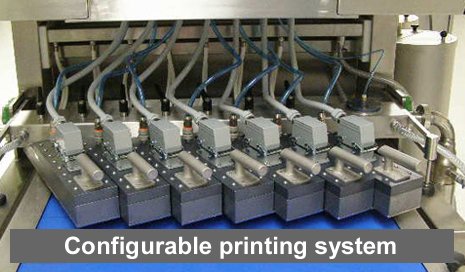

Printing system

The FoodJet printer has a flexible, modular architecture that can be configured to any production process. This allows for a vast number of decorating and filling options. Changing the angle between the printer head and movement direction of the conveyor allows the resolution to be set. Using heads behind one another permits “multi-color” printing, where colors are applied in different layers on top of each other. Placing heads next to each other allows for a wider working area.

While the physical placement of the printer head offers a lot of possible configurations, other variables like nozzles, pressure and dispensing time also increase the printing possibilities.

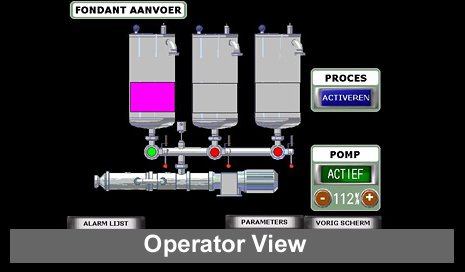

The printer is controlled by two PLCs, and the mechanism to program the various dispensing-pattern options is a homegrown solution, explains de Grood. Sensors like proximity switches and photocells are used for alignment. Depending on resolution, the speed of the printer can be up to 30 m/min with resolution as high as 30 dpi. The system has a reaction time of 200 µs. And with camera, the system accuracy is better than +/-1 mm. The HMI allows the operator to choose product, pressure and shutter times of valves. However, the camera runs autonomously.

Overnight

Typical for the food industry, many products need to be manufactured continuously, and, once a process stops, the machine needs to be shut down and cleaned because products cool down and harden or dry. "The FoodJet printer is a closed system, which prevents the product from drying or cooling," explains de Grood. "This means that it has no problem standing idle for hours or even overnight."

The traditional food decorating method is manual application or, if the process is automated, using masks and mechanical restraints. Area filling is done by applying a liquid curtain under which the food products are moved on a mesh conveyor. Another filling method involves partially submerging the products in a bath to apply the substance.

The baths and curtain processes especially require an extensive cleaning procedure when switching between products—for example, when switching to a different color frosting or switching from milk chocolate to dark chocolate. Because the FoodJet printer is a closed system, the switch can be done by connecting the reservoir with the new product and flushing the system before connecting the return flow to the reservoir. "A closed system prevents mixing of product ingredients or environmental contamination to ensure the best possible hygiene and food safety," says De Grood. "One of our customers managed to reduce the time it took him to switch between decoration fluids by 90%, as he no longer needed to spend four or five hours cleaning his machine. The transition time with the FoodJet printer now only takes several minutes."

Machine-vision smart-camera

The additional of a machine vision option to the FoodJet printer came about after a customer approached De Grood with an application where it was virtually impossible to mechanically align the food products so they could be decorated properly.

"A lot of bakery products would be almost impossible to handle by the FoodJet printer if it did not offer a vision option," explains de Grood. "These include fragile products which get damaged if handled too much by mechanical means for alignment and products with non-uniform shapes. Both of these situations can be solved by the vision system which measures the product's exact position and dimension."

Another advantage of using a vision system is flexibility. The FoodJet printer with the vision option allows for ultra-fast switching between food products. There is no need for food manufacturers to change any mechanical alignment tools or other sensors to work with a larger or differently shaped product.

The FoodJet’s vision system is based on a Matrox Iris GT smart camera. The application was developed with Matrox Design Assistant, an integrated development environment that is bundled with the camera. The software allowed De Grood to create a flow chart of the application instead of coding programs or scripts. This eliminates the need to program in any standard programming language like Basic, C, C++ or C#.

A number of Design Assistant tools or flow-chart steps were used. The location and size of products need to be measured, so calibration of the system is necessary. Image processing filters, blob analysis and model finder—geometric pattern recognition—steps were also used to get the required results. "The flow chart is configured and tested in Design Assistant, an interactive design utility that runs on a PC, and then uploaded to the camera," explains de Grood.

With Matrox Design Assistant, an application is created by constructing a flow chart using ready-made or custom tools instead of writing traditional program code, explains Fabio Perelli, smart camera product manager for Matrox Imaging. "Once development is complete, the project, or flow chart, is uploaded and stored locally on the Matrox Iris GT smart camera," he says. "The project is then executed on the smart camera independent of any PC and, in this case, is monitored and controlled from the PLC."

DVC, the Dutch distributor for Matrox Imaging, developed a custom step for communicating with the PLC. The ability to create custom steps is one of the features of the Matrox Design Assistant environment, enabling users to insert application-specific logic on their own. This step calls an .exe file that DVC made for communicating with the PLC. The timing of the communication between the Iris GT smart camera and PLC was critical. "It took a little while to get the camera and the PLC in sync but after a day of tweaking, the communication ran smoothly," says de Grood.

Several smart cameras were evaluated by De Grood for the printer’s vision system but Matrox said the application was possible and the Iris GT's price was less than other alternatives, explains de Grood.

It also offered the IP67 form factor de Grood wanted. "The IP67-rated housing was welcomed since this makes for easy integration in the system, without the need for additional protection against moisture," he says. "To keep the system as compact as possible, we wanted to have the camera and processing combined into one package." The printers also link back to the enterprise system, offering the possibility of full remote assistance worldwide.

The future

De Grood emphasizes that the FoodJet printer can be used by industries other than food processing. “Every production method that applies thick, highly viscous fluids is a potential market. Some non-food examples are decorating ceramic tiles, applying complex glue patterns to printed circuit boards, ICs, flat screen components, etc. or printing a company logo on cosmetic creams to show consumers that they have purchased a real product and not a cheap counterfeit. The possibilities are endless.”

Direct Link: Smart-Camera Matrox Iris GT Overview

http://www.rauscher.de/...

AUTOMATICA

Halle B2 – Stand 302

RAUSCHER

Johann-G.Gutenberg-Str. 20

D-82140 Olching

Phone +49 81 42 / 4 48 41-0

Fax +49 81 42 / 4 48 41-90

E-Mail: info@rauscher.de

www.rauscher.de

For more information about Matrox Iris GT please contact RAUSCHER

- Sales in Germany and Austria