The first customers have used the software to develop new ship/block rules for pickling lines, which now no longer depend on the subjective judgement by inspection personnel but use data from several inspection systems. Following first tests with simple rules, the companies have developed comprehensive rule sets all by themselves and within an extremely short time. They will soon be using the QualityMonitor solution to assess the strip meter by meter, enabling optimized use of the individual strip sections.

The combined software package comprising the LogicDesigner and the QualityMonitor makes it easy for the mill operator to set up simple and objective rules for the release of products, even across several plants, and integrate data from measuring systems of any kind. As the rules can be swiftly changed if needed, the criteria for the release of a product can be adjusted to changing customer requirements in virtually no time. For example, the operator can set up customer-, material-, order- and line-specific rules and activate these rules for any defined period of time. This makes the operator independent of statically programmed rules and inflexible rules as specified in quality manuals.

The advantage: Decision-making criteria are dynamically adapted - an important aspect in times of varying demand, small lot sizes and low utilization rates of production plants.

Thanks to the high spatial resolution of the measurement data, decisions can now also be made for short strip sections, e.g. per current meter, improving overall material utilization. The objectified process also ensures that different lines supplying the same customer all produce the same quality ("one quality to the customer").

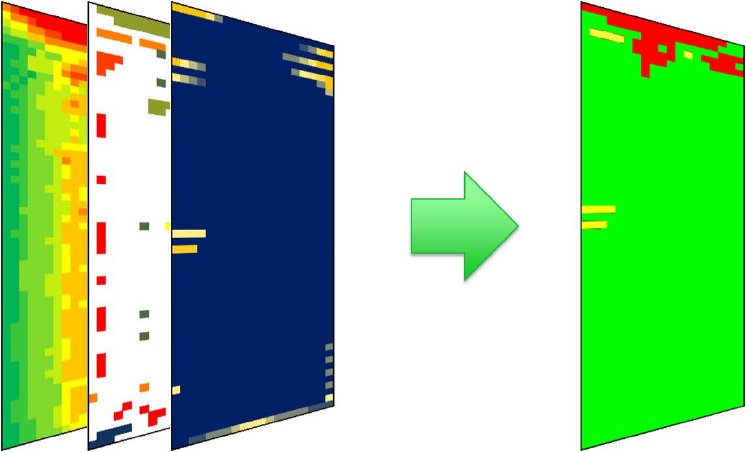

The QualityMonitor supports quality grading at the line. It integrates the results from various measuring systems and even incorporates data from new systems for which experience and rules are still developing and cannot be taken into account by commonly used release mechanisms. These include surface inspection systems, which deliver different surface information than the visual inspection personnel, as well as temperature scanners and inline systems measuring tensile strength, yield points and surface roughness.

The software functions are transparent throughout the process: Key rules for the ship or block decisions are displayed for each specific situation, complete with the associated measuring data.

When making the rule-based quality decision, the QualityMonitor takes into account not only individual values but also combinations of data delivered by different measuring systems. Thus it is possible to decide "block" in a situation where the individual measurements are still within the specified tolerance limits, but the overall quality is inacceptable for the customer.

The LogicDesigner defines and administers the rules which the QualityMonitor applies. The decision criteria can be swiftly defined and modified by the plant operator without requiring any external specialist support. Whenever a rule is changed, the "Feedback Function", i.e. simulation based on historical data and archived decisions, immediately displays which consequences this change has on the yield of the line.