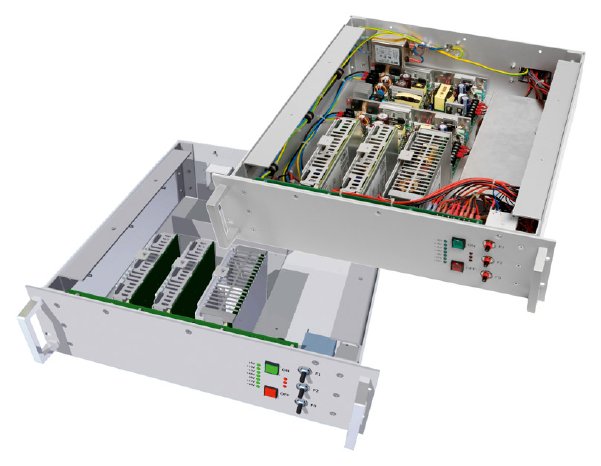

Instead of manufacturing the usual mechanical prototype, EPLAX's development team created an exact 3D model, a virtual prototype, using the CAD system. The virtual model was then used to plan, measure, and position all connections and controls. This procedure cut not only the usual development cost, but saved a considerable amount of time in the bargain. The new power supply unit is a perfect fit and could be integrated in the system swiftly and without problems.

Virtual prototype saves time and money

EPLAX power supply integration uses high-precision 3D CAD models

Instead of manufacturing the usual mechanical prototype, EPLAX's development team created an exact 3D model, a virtual prototype, using the CAD system. The virtual model was then used to plan, measure, and position all connections and controls. This procedure cut not only the usual development cost, but saved a considerable amount of time in the bargain. The new power supply unit is a perfect fit and could be integrated in the system swiftly and without problems.