Hot environment - new steel - ingenious joining process

The power plant construction sector is booming worldwide - plans everywhere have been confirmed, orders for the necessary components have been put out to tender multiple times or have already been awarded. The new power plant generation is becoming more efficient and environmentally friendly in operation than previous plants. The engineers have continued to optimise the process technology to achieve this end, and the operating temperatures of the plants have been increased considerably. The term "700 degree power plant" is on everyone's lips. For plant construction this means using more pressure-resistant, thick-walled pipes made from high temperature steels such as P91 and its successor P92 (X 10 CrMoVNb 9-1, WKN 1.4903) conforming to the ASTM standard (American Society for Testing Materials). The key quality features of this new steel grade are the values for high creep rupture strength which also applies without restriction as the benchmark for every weld seam on these pipes.

Exactly how modern, efficient and technologically advanced automated welding technology handles this task was demonstrated to the guests in a tightly organised programme immediately following their arrival and a tour of the factory: P91 pipes of 620 millimetres in diameter and a wall thickness of 180 millimetres were joined using a narrow gap torch in the TIG orbital welding process using hot wire additive (fig. 2). No arc welding process combines productivity with quality in a more effective way. The joined seams offer 100 percent penetration, are x-ray proof, and meet the highest of requirements for metallurgic and mechanical quality values (fig.3).

Theory at the leading edge of practical application

In the next theoretical part of the programme, the host and Polysoude's CEO, Hans-Peter Mariner, offered an in-depth insight into the requirements, options and limits as well as the latest developments in narrow gap welding. This presentation highlighted that with wall thicknesses of over 60 millimetres, the welding time is shortened by a factor of five to ten in comparison to conventional TIG processes with a traditional V seam - fewer layers need to be welded in total and considerably less metal additive is used; with the addition of already "pre-heated welding additive" (hot wire), the welding time is also reduced, without generating more energy in the weld.

The welding characteristics of the parent material are the decisive factor in the application of the narrow gap process. Technical advances in equipment technology such as automatic centring, HF-free ignition, seam preparation and optimised gas protection further increase the application limits. The geometry and gap width of the weld groove are based on the mechanical properties of the materials being joined (fig.4), with the shrinkage characteristics of the seam being particularly important here.

The choice between orbital welding and welding on a rotating workpiece depends on the task itself. The torch position and process variant decides the thickness of the individual weld beads and therefore the productivity. Certain alloys only permit vertical down welds, others only allow for vertical up welds. The solution: Weld heads with symmetrical wire feeds in front of and behind the torch for welding in both directions.

Ostensibly insignificant basic conditions were also covered: Accessibility of the welding area; clear identification of the parent and welding additive materials, costs for the preparation and weld tests to calculate the parameters as well as the experience and qualifications of the welders and the necessary equipment.

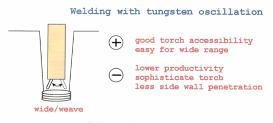

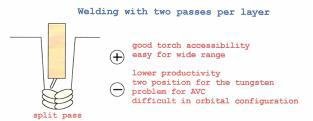

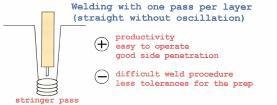

Another key part of the programme was a presentation on the three different narrow gap welding techniques: One single pass weld per layer and torch or workpiece revolution (fig. 5). Or alternatively, a dual pass welding next to one another, when the seam preparation or positioning exceed the required narrow tolerances of a few tenths of a millimetre for one stringer bead per layer. The same applies if the characteristics of a delicate parent material demand limited shrinkage stresses or the necessary energy per unit length of weld for a bead to melt both workpiece edges is too high. TIG narrow gap welding with a shuttle-motion electrode is ideal with very large wall thicknesses of 150 to 200 millimetres. In particular if the necessary boundary conditions such as accuracy of the seam preparation, handling of the shrinkage process and torch design cannot be ensured for joining using one stringer bead per layer with a reasonable amount of work.

However, the equipment technology required for this is becoming much more complex. This means that it can only be positioned with precision when the plants are of a sufficient size.

Turnkey solutions: turbines for every power plant

The second day of the forum began with an in-depth presentation on "Applications, solutions - implemented projects". During the past financial year, in boiler construction in power plants worldwide alone, Polysoude fitted more than 30 made-to-measure circumferential seam welding systems for automated TIG welding and several hundred orbital welding systems for custom applications. Following a comprehensive question and answer session, the perfected, mechanised welding process was demonstrated on a rotating part.

Expansive power plant construction means that every power plant also needs to be fitted with turbines. To conclude the expert forum, the turnkey solutions offered by Polysoude for joining rotors were on display for participants. To this end, a narrow gap welding system for manufacturing turbine rotors of up to 300 tonnes was set up in the factory hall. A level of welding system performance for which even insiders openly declared their approval.

A new session for Experts in Narrow Gap Welding will be organised by Polysoude, in English language, by the end of March. Persons that may be interested can request more details by phone on +33 (2) 406811-74 or by email info@polysoude.com.