The simultaneous inspection of the surface quality and geometry of profiles, cables and tubing through an optical inline process for the first time provides the possibility of capturing all relevant geometrical parameter by a single system. The line operators can grasp any variations in the production process at a glance. They can diagnose the problem and intervene before out-of-spec material is produced.

The ProfilControl-DualHead is a combination of one Pixargus surface inspection system of the ProfilControl-Surface series and one ProfilControl-Dimension contour measurement system. In designing the system, Pixargus paid special attention to achieving a highly compact construction of the system because in extrusion lines the space available for the installation of inspection systems is usually very limited.

In addition to the low space requirement, combining two different Pixargus systems into one common quality station provides another important advantage: both systems have identical, intuitive user interfaces. An operator accustomed to one of the system, will be able to familiarize with the other system in no time. By large, clearly visible touch screen buttons the user can easily navigate through the operator menu.

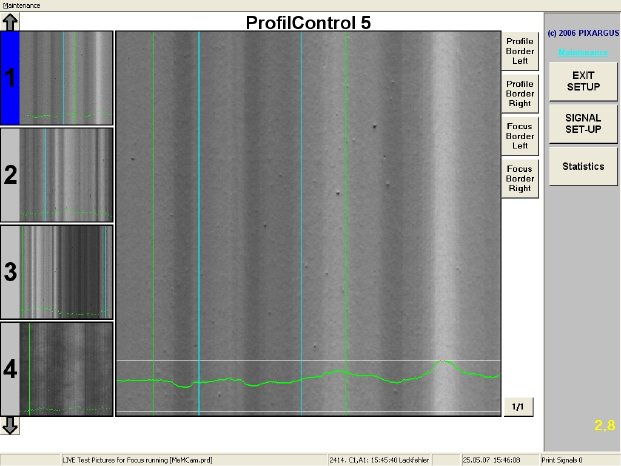

Inline surface inspection systems of the ProfilControl-Surface series detect and classify defects such as pimples, bubbles, breakouts, inclusions or holes. Cameras scan the entire surface. A “surface map” as well as individual defect images are displayed on the touch screen. During final inspection it is thus possible to locate those areas of the profiles which do not comply with the required quality standards and which have to be sorted out.

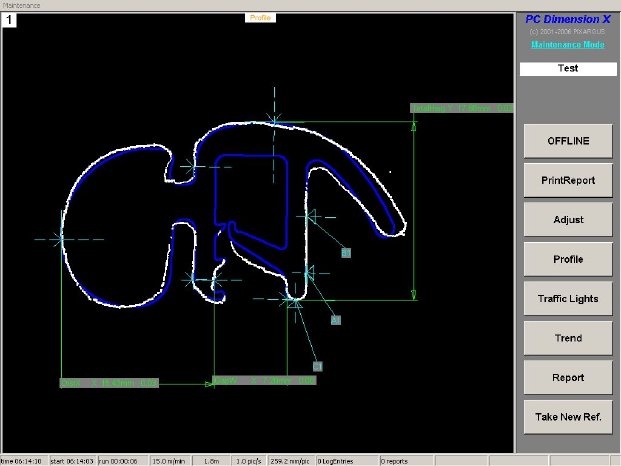

The inline profile measurement systems are based on the Pixargus ProfilControl-Dimension series, which has proven successful worldwide at leading manufacturers of rubber and plastic profiles. Cameras arranged around the profile scan the complete contour of the extruded profile. Dedicated software calibrates it against the contour of a reference profile. The profile is graphically displayed complete with its allowable tolerances.

The sturdy design of the two systems makes them suitable for the environmental conditions prevailing at the production line. Long-life LEDs are used as light sources.