One more time, Pixargus has made an important contribution to making the measurement of profiles more accurate, simpler and more flexible: Whereas in the past it was necessary to guide the profiles accurately through the measuring head, today the measuring heads automatically follow the position of the profile. Moreover they rotate whenever the profile twists.

The systems are an enhancement of the existing PCD-X360 profile measurement series. Thanks to the DHP (Dynamic Head Positioning) function complex profile guiding solutions are a thing of the past. Also in a normal guiding system, some lateral movement or twisting of the profile cannot be completely avoided during production. If this happens to a profile with a very finely structured geometry, even such minor movements can cause the profile to move out of the line of vision of the cameras. In such cases the DHP module makes sure that the profile and the cameras are at all times in optimal positions relative to each other. Thus it is no longer necessary to manually set up the system for a production start or manually readjust the system during production.

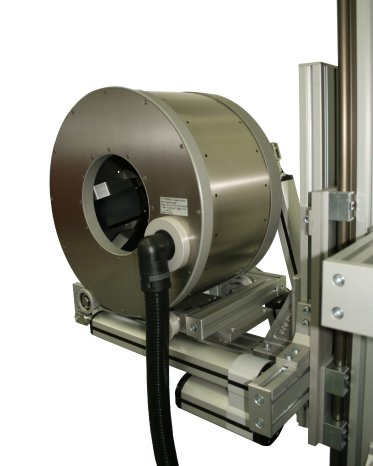

Pixargus solved this challenging task by means of an intelligent "autofocus" feature. The system recognizes the profile position in the measuring space as well as its rotary position. Based on this the system adjusts the measuring head in three axes. This ensures that the optics views the profile at all times from the right direction.

Optical systems from Pixargus are used in the manufacture of profiles, cables and tubing for capturing most minute variations in dimensions during running production – inline, gaplessly and objectively.

These inline profile measurement solutions are based on Pixargus’ ProfilControl-Dimension series, which has proved highly successful in the production of rubber and plastic profiles at leading profile manufacturers throughout the world. Cameras arranged around the profile capture the complete extruded contour, while a software is comparing the measured dimensional values with a reference profile. The profile is graphically displayed complete with the tolerance bands.

All systems are sturdily designed to withstand the prevailing environmental conditions during production.

Pixargus at DKT-IRC in Nuremberg, Germany: hall 12, booth 12-436