Pixargus recently supplied the first 360 degree inline profile measurement system of the ProfilControl-Dimension HT-740 series to a leading German manufacturer of rubber profiles for the automotive industry. The system was developed specifically for use at high ambient temperatures. This makes it an ideal solution for the measurement of rubber profiles directly downstream of the extruder. In rubber profile extrusion lines it can be installed directly before or behind the heating channel.

The instrument is highly useful in practical operation, as it provides the possibility of capturing the relevant dimensions of technological profiles in real time directly at the start of the extrusion line.

In combination with a second measuring head installed at the end of the extrusion line it is possible – virtually in no time - to establish automated correlations between the initial dimensions at the extruder and the final dimensions at the end of the line. In this way the operators know minutes in advance whether a profile will have the correct size at the end of the extrusion line or whether it is necessary to intervene. If deviations are detected already in the extrusion or curing zones, the system can be configure to send alarm messages to the operator or influence the process through an automated control procedure.

In environments with temperatures exceeding 60 °C, non-cooled systems easily reach their limits. Therefore the cameras and light sources of the Pixargus system are actively cooled by a closed circuit of liquid cooling media. Thus the calibration of the system remains stable at all temperatures.

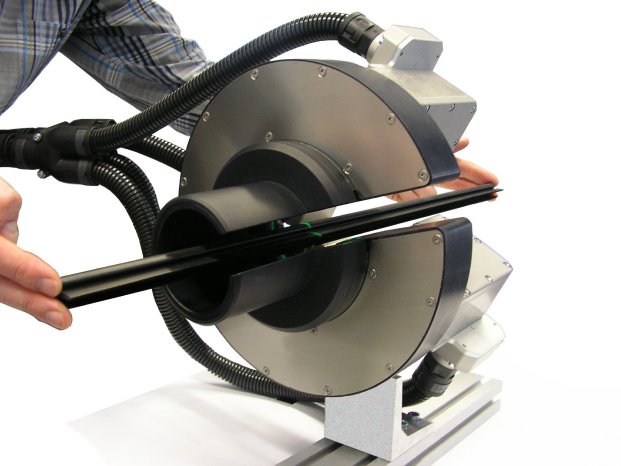

Four cameras arranged around the profile scan the complete contour of the extruded profile, measure the contour and calibrate it against the contour of a reference profile.

The profile and its allowable tolerances are graphically displayed, enabling the operating team to easily recognize any tolerance deviations and take immediate corrective action, if necessary. Operator guidance is convenient, intuitive and user-friendly. By large, clearly visible touch screen buttons the user can easily navigate through the operator menu.

The high-temperature system is based on the Pixargus “ProfilControl-Dimension” series, which has proven successful worldwide at leading manufacturers of rubber and plastic profiles.

In designing the measuring head, Pixargus paid special attention to achieving a highly compact construction of the system because near the extruder or the heating channel the space available for the installation of a measuring head is usually very limited.

The system is available in a closed version and with an open C-frame. The latter version can be introduced into the production line at the desired position during running operation.