The last few years have seen a dramatic rise in the demand for precision tubing. This growth has been triggered not only by applications in medical technology, in the automotive industry and as a result of advancing automation. Tubings are also frequently used in sealing systems which are made of a solid base material and a soft, sealing component.

Precision tubing must fit exactly into the connecting elements. No matter whether used as a hose or a sealing element, leakages are not only undesirable. They must rather be avoided by all means because they can be dangerous. For tubings to fit perfectly, not the diameter but the circumference is the key parameter. As soft material easily deforms during production – simply due to gravity or during reeling – it used to be a problem for many tubing manufactures to exactly measure the circumference of the products.

Optical measuring systems working with just a few axes and according to the shadow principle or contact stylus measurements capture the diameter only point-wise. Such systems provide exact circumference measurements only in cases where the tubing material is circular or regularly oval shaped and where the orientation of the axis is known. As soft material often deforms irregularly, two-axis measurements are unable to deliver correct circumference data. Therefore there is no reliable information as to whether the tubing will have the exact mating size.

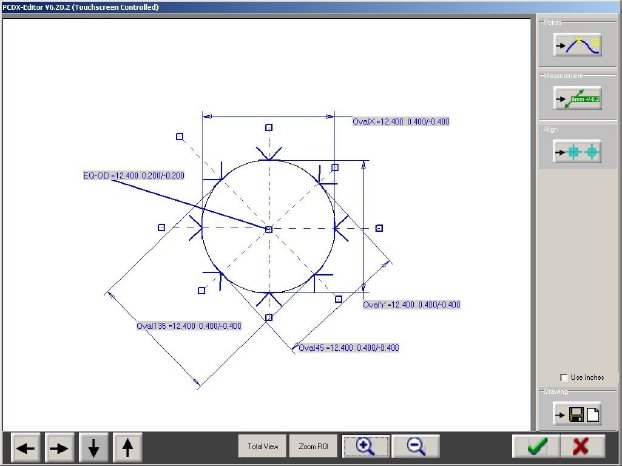

The new “ovality module” developed by Pixargus solves this problem by computing the true outside diameter and the circumference from the complete outside contour independent of the shape and orientation of the tubing. The proven Pixargus ProfilControl dimension measurement systems illuminate the circumference of the tubing from all directions. This enables them to capture the complete profile, even if it is irregularly shaped. From these measured data the new module computes the exact circumference of the tubing.

Thanks to the “ovality module” the production process can now be precisely controlled. Intervention is possible at any time because the system works inline. The manufacturers of precision tubing can produce products with closest dimensional tolerances. Even when processing dimensionally instable material, they can now for the first time guarantee that their products feature the correct outside diameter.

Pixargus ProfilControl dimension gauges can be used with tubing diameters between 2 and 170 mm and with all light reflecting surfaces. They are also suitable for the inspection of Duplex hoses.

The “ovality module” is an add-on software product, which can easily be connected to existing Pixargus ProfilControl systems. The tubing manufacturer does not have to change his usual operating practice. The system is conveniently calibrated by means of a calibrated adjusting piece used instead of the tubing material.

Like other Pixargus products the system is highly user-friendly: it only takes three mouse clicks to start the measurement, monitor the tolerances and compute the ideal circumference of the oval circle.