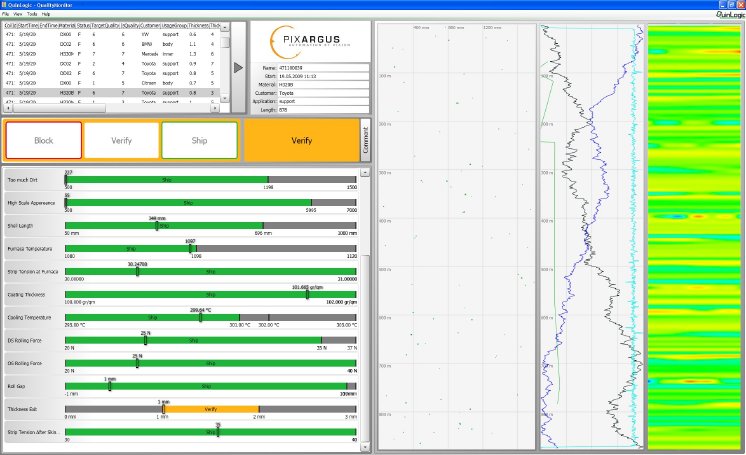

The QDS Decision Server collects measured data from the various plants of the production route and from quality assurance systems of all kinds, e.g. from dimensional profile measurements or temperature data measured during the extrusion process. All these data are combined into a graphical display of the total production route relative to the length of the product. In this way the system enables the operator to track the quality of the profile through all production stages and optimize the quality and yield of the entire extrusion plant.

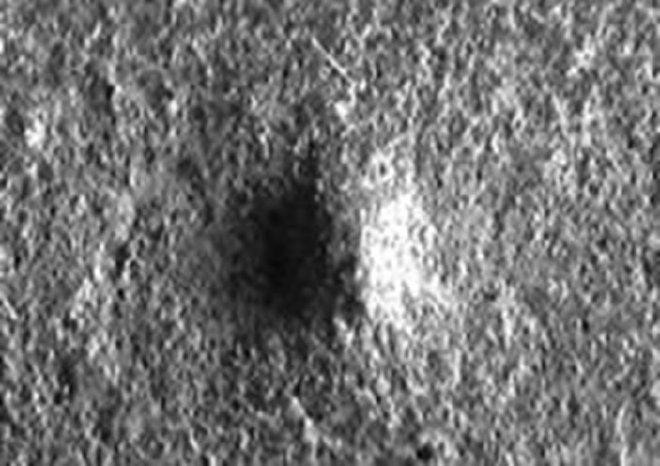

QDS also incorporates data from new systems for which experience and rules are still developing – for example data from surface inspection systems – and which cannot be taken into account by commonly used release mechanisms.

With QDS, release rules can be defined in a simple manner. The “ship or block” decision will no longer be based the subjective judgement by the human operator but on objective quality criteria. For example, the operator can set up customer-, material-, order- and line-specific rules and activate these rules for any defined period of time. This makes the operator independent of statically programmed rules and inflexible rules as specified in quality manuals. In this way it is guaranteed that different lines supplying the same customer all produce the same quality.

When making the rule-based quality decision, QDS takes into account not only individual values but also combinations of data delivered by different measuring systems. Thus it is possible to decide “block” in a situation where the individual attributes are still within the specified tolerance limits, but the overall quality is inacceptable for the customer.

As the rules can be changed swiftly, the criteria for the release of a product can be adjusted to changing customer requirements in virtually no time. The advantage: Decision-making criteria become dynamic. This is an important aspect in times of varying demand and small lot sizes.

Thanks to the high spatial resolution of the measurement data, decisions can now also be made for short product segments, e.g. per current meter. This feature improves overall material utilization, as it enables each individual profile segment to be assigned to an optimized use.

As all production data are stored in a common database, it is possible at any time to make an analysis of historical data, for example, about the influence of temperature and pressure on certain profile dimensions.

Another important aspect for quality optimization is the reliability by which “What if … “ questions can be answered. When a product is inspected in an inline process based on a defined set of quality criteria and threshold values, it would often be interesting to know what the decision - “ship” or ”block for review” – would have been if a different set of criteria and tolerances had been chosen. Here QDS provides easy and speedy analyses, resulting in optimized line throughput and enhanced product quality.

Pixargus at DKT-IRC: Hall 12, Stand 12-436