Alongside added functionality, the newest version of the CAM software program hyperMILL® brings users of hyperMILL®'s CAD integrations up to date. Users of these versions can access all of the software's functional benefits in an integrated manner, including the new millTURN module.

An integrated CAD/CAM solution for continuous processing The advantage provided by the CAD-integrated CAM solutions is that they enable the realisation of continuous process chains. The CAD and CAM systems both access the same pool of data. A uniform data model is used during the entire process in order to ensure the accuracy and transparency of the manufacturing process and to prevent errors. The standard user interface from the CAD environment simplifies CAM programming and raises the user's acceptance of the CAM solution.

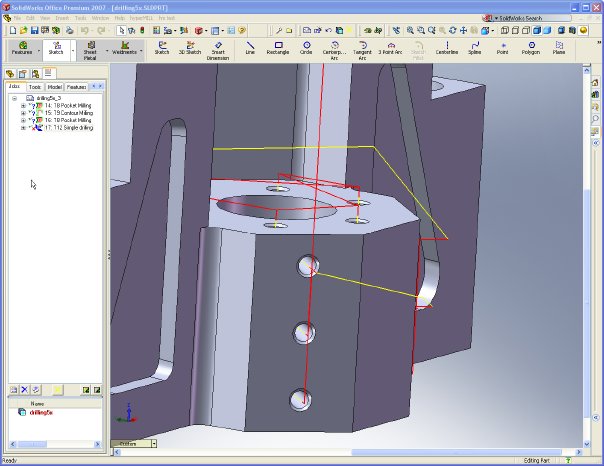

Support for SolidWorks® and Autodesk® Inventor™ 2008 For the first time, hyperMILL® V9.7 realises continuous process chains for SolidWorks® CAD users. In addition, hyperMILL® V9.7 already supports the recently released Autodesk® Inventor™ 2008. hyperMILL® thus supports all leading CAD applications in its current version as an integrated CAM solution.

hyperMILL® - A CAM solution with high-end strategies hyperMILL® is probably the most modern CAM solution available today. hyperMILL® offers users an array of strategies for 2D, 3D, HSC and 5-axis machining, as well as milling and turning, in one user interface. Programming efforts are reduced with sophisticated feature technology, including feature recognition, automatic mapping of hole and pocket features, feature list, feature browser, macro technology and macro database. The postprocessors, tailored to specific machines, controllers and manufacturing processes, ensure that the CAM programs are processed seamlessly on the machine. With new workspace monitoring the user can check in advance whether the machining job can be performed within the given workspace or whether limit switches will be crossed. The unique 'best fit' function automatically optimises machining with a view to the available work space and also allows optimal space usage when small or limited machines are used. For companies, this means an all-encompassing manufacturing concept and a flawless machining process with the best possible results.

Additional information is available on request or on our website at www.openmind-tech.com.