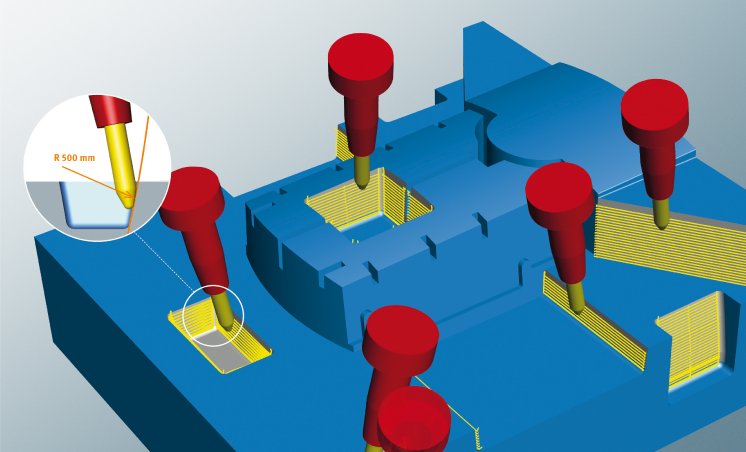

‘Tangent plane machining’ offers users a major boost in efficiency for finishing planes and free-form surfaces. Using conical barrel cutters allows for larger path distances for the same theoretical scallop height. The OPEN MIND machining strategy takes advantage of the extremely large radius of the barrel shape, which allows for optimal inclination to the faces. This makes it possible to achieve considerably shorter machining times and a high level of surface quality. The innovative strategy is easy to program, highly efficient and reliable thanks to the collision check performed on the toolpaths.

Toolkit with special strategies

Version 2016.1 sees OPEN MIND showcase the modular hyperMILL® MAXX Machining performance package. It offers a range of optional high-performance strategies for roughing and finishing. The package includes the HPC roughing module, currently called hyperMAXX®, that is powered by Celeritive’s Volumill kernel.

Mill-turning with more performance

The mill-turning innovations and optimisations also promise better performance. The user interface is now even more transparent for making inputs easier. The new cutting edge position management feature makes it possible to better define the tool cutting edge and its position.

More CAD for CAM – hyperCAD®-S

hyperCAD®-S, the CAD system for CAM, is packed with many innovations and extensions, including extended associativity with hyperMILL® and the new surface command for support during 5axis swarf cutting.